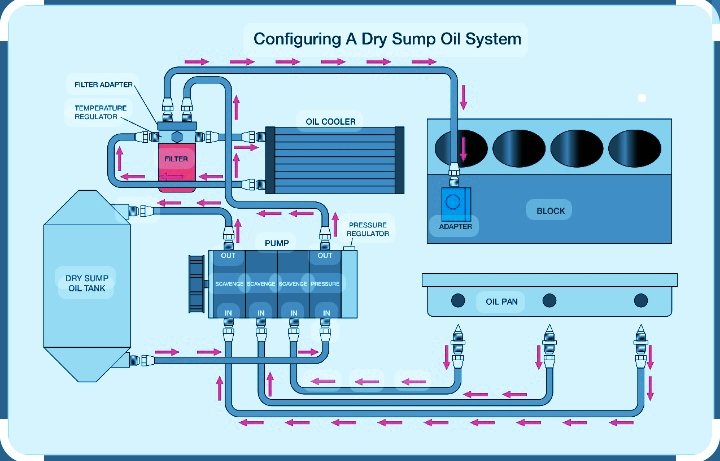

In the realm of high-performance racing, particularly in dirt track racing, the efficiency and reliability of the engine’s lubrication system are paramount. dry sump system.

This is where dry sump systems come into play, offering a sophisticated solution to the challenges posed by traditional oiling methods.

Unlike the conventional wet sump system.

Where oil is store in a pan beneath the engine, a dry sump system utilizes an external reservoir to hold the engine oil.

This fundamental difference brings a range of benefits crucial for the rigorous demands of racing environments.

One of the primary advantages of a dry sump system is its ability to improve oil circulation.

In high-speed racing conditions, maintaining optimal oil flow is critical to ensure that all engine components are adequately lubricate.

The dry sump setup uses multiple scavenging stages to draw oil from various parts of the engine and pump it into the external reservoir.

This method not only ensures a consistent oil supply but also helps in cooling the oil more effectively.

Thereby enhancing the overall performance of the engine.

Another significant benefit of dry sump systems is the reduction of oil starvation.

In traditional systems, high-speed cornering or rough terrain can cause the oil to slosh away from the pickup, leading to momentary lapses in lubrication.

Such occurrences can be detrimental to the engine’s health.

However, with a dry sump system, the risk of oil starvation is minimize as the scavenging pumps ensure continuous oil flow regardless of the car’s orientation or the track conditions.

This reliability is indispensable in dirt track racing, where uneven surfaces and aggressive driving are common.

Furthermore, dry sump systems contribute to enhanced engine reliability.

By relocating the oil reservoir outside the engine.

these systems allow for better control over the oil’s temperature and pressure.

This external placement also helps lower the engine’s center of gravity.

Which can improve the vehicle’s handling and stability. Collectively, these advantages make dry sump systems an integral component of high-performance racing.

Providing the requisite lubrication and reliability needed to excel in competitive racing scenarios.

The Role of a 5 Stage Dry Sump Pump

A 5 stage dry sump pump is an essential component in high-performance engines, particularly in the realm of dirt track racing.

Unlike traditional oil pumps, a dry sump system utilizes multiple stages to separate the functions of oil scavenging and pressure maintenance.

This separation is crucial for maintaining optimal engine performance under the extreme conditions often encountered in dirt track racing.

The 5 stage configuration allows for more precise control and management of engine oil, thereby enhancing reliability and efficiency.

The first four stages of a 5 stage dry sump pump are dedicate to scavenging.

Each scavenging stage is responsible for extracting oil from different areas of the engine.

ensuring that excess oil is remove and returned to the oil reservoir.

This process prevents oil accumulation in the crankcase.

Which can lead to power loss and increased wear on engine components.

By effectively managing oil levels, these scavenging stages help maintain a consistent oil supply.

Which is vital for engine longevity and performance.

The fifth stage is the pressure stage, which delivers a steady flow of oil back into the engine.

This stage ensures that all engine components receive adequate lubrication, reducing friction and heat generation.

The pressure stage is meticulously calibrated to maintain optimal oil pressure, adapting to the engine’s demands during various driving conditions.

This adaptability is particularly beneficial in dirt track racing.

Where rapid changes in speed and direction can significantly impact oil distribution.

One of the primary advantages of a 5 stage dry sump pump in dirt track racing is its ability to handle the rigors of high-speed, off-road environments.

The sophisticated design of the pump provides consistent oil flow, even during aggressive maneuvers and uneven terrain.

This reliability underscores the importance of selecting a high-quality.

5 stage dry sump pump to ensure peak performance and durability in competitive racing scenarios.

Key Features to Look for in a 5 Stage Dry Sump Pump

When selecting a 5 stage dry sump pump for dirt track racing.

several key features should be carefully evaluated to ensure optimal performance and longevity.

One of the primary considerations is the material quality used in the construction of the pump.

High-grade aluminum or billet materials are often preferred due to their lightweight nature and superior strength.

Which can withstand the rigorous demands of dirt track racing.

Durability is another critical factor. A robust 5 stage dry sump pump must endure extreme conditions.

Including high temperatures and abrasive particles commonly encountered on dirt tracks.

Look for pumps with reinforced seals and wear-resistant coatings to enhance durability.

Efficiency is equally important, as a highly efficient pump will ensure consistent oil flow.

Minimizing the risk of engine wear and failure.

Advanced design features such as optimized rotor profiles and precision machining can contribute to improved efficiency.

Ease of maintenance is a practical consideration that can save both time and money.

Pumps designed with modular components and accessible service points allow for quicker inspections, repairs, and part replacements.

Compatibility with different engine types is another essential feature.

Ensure that the chosen 5 stage dry sump pump is adaptable to your specific engine configuration.

whether it be a V8, inline-four, or other setups.

This flexibility can significantly impact performance and ease of installation.

Finally, customization options can provide a competitive edge tailored to specific racing needs.

Many manufacturers offer customizable pumps that can be fine-tuned to meet the unique requirements of different racing environments.

Customizable features might include adjustable pressure settings, interchangeable gears, and bespoke mounting options.

This level of customization ensures that the pump not only meets but exceeds the demands of high-performance dirt track racing.

Top Brands in the Market

When it comes to selecting the best 5 stage dry sump pump for dirt track racing.

Choosing a reputable brand is crucial.

Several companies have established themselves as leaders in this niche.

Delivering high-performance and reliable products that meet the rigorous demands of dirt track racing.

Among these, Dailey Engineering, Moroso, and Peterson Fluid Systems stand out for their innovation, quality, and industry recognition.

Dailey Engineering is renowned for its precision and engineering excellence.

The company specializes in dry sump systems and has a strong reputation.

For producing pumps that offer superior oil control and reliability.

Their products are design with the latest technology.

Ensuring that racers can rely on consistent performance under the most demanding conditions.

What sets Dailey Engineering apart is their commitment to innovation and continuous improvement.

Making them a top choice for many professional racers.

Moroso Performance Products is another leading brand in the racing industry, known for its extensive range of high-quality racing components.

Moroso’s 5 stage dry sump pumps are particularly popular due to their durability and efficient oil scavenging capabilities.

The brand has built its reputation on providing products, that not only enhance engine performance.

but also withstand the harsh environments of dirt track racing. Their attention to detail and rigorous testing processes ensure that each pump meets the highest standards of quality and reliability.

Peterson Fluid Systems is also highly regarded in the racing community. Known for their robust and efficient dry sump systems.

Peterson’s 5 stage pumps are designed to maximize oil flow and minimize engine wear.

The company prides itself on its advanced engineering and customer-focused approach.

Offering customizable solutions to meet the specific needs of each racer.

Peterson Fluid Systems’ commitment to excellence and their proven track record make them a trusted name among dirt track racing enthusiasts.

In summary, Dailey Engineering.

Moroso, and Peterson Fluid Systems are top brands that consistently deliver high-performance 5 stage dry sump pumps.

Their dedication to quality, innovation, and reliability sets them apart in the competitive world of dirt track racing.

Making them preferred choices for racers seeking the best equipment for their vehicles.

Comparative Analysis of Popular Models

When it comes to selecting the best 5 stage dry sump pump for dirt track racing, several popular models stand out in the market.

Each model brings its own set of strengths and potential drawbacks.

In this section, we will conduct a detailed comparative analysis of these models based on performance, price, durability, and customer reviews.

Performance is a critical factor for any dirt track racing enthusiast.

The Barnes 5 stage dry sump pump is renowned for its superior oil flow and pressure stability, ensuring optimal engine lubrication during high-speed racing.

Similarly, the Dailey Engineering 5 stage pump offers exceptional performance, particularly noted for its high-efficiency rotor design that reduces parasitic drag on the engine.

Price is another essential consideration.

Models like the Peterson Fluid Systems 5 stage pump are known for their cost-effectiveness, providing robust performance at a more accessible price point.

On the other hand, the Aviaid 5 stage pump tends to be on the higher end of the price spectrum, reflecting its advanced engineering and premium materials used in construction.

Durability is a key factor influencing the longevity and reliability of dry sump pumps.

Many users have praised the Moroso 5 stage pump for its rugged construction and long-lasting performance, even under the most demanding racing conditions.

The Barnes model also scores high in terms of durability, with its precision-machined components and robust build quality.

Customer reviews offer invaluable insights into real-world performance and user satisfaction.

The Dailey Engineering pump consistently receives high marks from racers for its ease of installation and maintenance.

Meanwhile, the Peterson Fluid Systems pump is often lauded for its excellent customer support and comprehensive warranty, adding value to its overall package.

In summary, each of these 5 stage dry sump pumps has its own unique advantages and potential trade-offs.

By considering factors such as performance, price, durability, and customer reviews, dirt track racing enthusiasts can make a well-informed decision that best suits their specific needs and preferences.

Installation and Maintenance tips

When installing a 5 stage dry sump pump for dirt track racing, attention to detail is paramount to ensure optimal performance and longevity.

Begin by gathering the necessary tools, including wrenches, screwdrivers, a torque wrench, and appropriate fittings.

It’s essential to have a clean workspace to prevent contaminants from entering the system.

Before starting, consult the manufacturer’s manual for specific instructions and torque specifications.

One common challenge during installation is aligning the pump correctly with the engine.

Misalignment can lead to excessive wear and potential failure.

Begin by mounting the pump bracket securely to the engine block, ensuring that all bolts are tightened to the recommended torque.

Next, align the pump pulley with the crankshaft pulley using a straight edge to verify alignment.

Install the drive belt, ensuring proper tension to avoid slippage or excessive wear.

Once installed, initial priming of the system is critical.

Fill the oil tank with the recommended type and quantity of oil, then manually rotate the pump to circulate oil through the system before starting the engine.

dry sump system

This step ensures that all components are lubricated, preventing dry starts that could damage the pump.

Maintenance of a 5 stage dry sump pump involves routine checks and cleaning procedures.

Regularly inspect the drive belt for signs of wear and replace it if necessary.

Check all fittings and hoses for leaks or damage, and tighten any loose connections.

Periodically change the oil and filter according to the manufacturer’s recommendations to maintain optimal lubrication and performance.

Additionally, inspect the pump’s internal components for wear or debris, and clean the screens and filters to prevent blockages that could impede oil flow.

Troubleshooting common issues is vital for maintaining the pump’s performance.

If you notice a drop in oil pressure, first check for leaks or blockages in the system.

Ensure that the oil level is adequate and that the pump is receiving the correct drive ratio.

If the pump is making unusual noises, investigate for possible misalignment or worn components that may need replacement.

By following these installation and maintenance tips, you can ensure the reliable operation of your 5 stage dry sump pump, ultimately enhancing the performance of your dirt track racing vehicle.

Real-World Performance and Case Studies

When evaluating the best 5 stage dry sump pump for dirt track racing, it is crucial to consider real-world performance and case studies.

Many professional racers and mechanics have shared their experiences, highlighting the significant impact these pumps have had on their racing outcomes.

These testimonials provide practical insights and serve as robust evidence of the effectiveness of these systems in demanding racing scenarios.

One notable case is that of a professional dirt track racing team that integrated a 5 stage dry sump pump into their high-performance engine.

The team reported a substantial improvement in oil pressure stability and engine reliability.

Prior to using the dry sump system, they frequently faced issues with oil starvation during high-speed cornering, leading to engine wear and failures. With the 5 stage dry sump pump.

Oil was consistently delivered to critical engine components, eliminating these problems and enhancing overall performance.

Another compelling example comes from an independent mechanic who services multiple dirt track racing teams.

He observed that engines equipped with 5 stage dry sump pumps exhibited significantly less wear and tear compared to those with traditional oiling systems.

The mechanic noted that the consistent oil pressure and improved lubrication provided by the dry sump pump reduced engine friction and heat.

contributing to longer engine life and more reliable performance during races.

Professional racer testimonials further underscore the advantages of using a 5 stage dry sump pump.

Several racers have mentioned that the enhanced oil management system allowed them to push their engines to higher RPMs without the risk of oil-related failures.

This increase in performance capability has been a game-changer, enabling them to achieve better lap times and more competitive results.

These real-world examples and case studies clearly illustrate the significant benefits of 5 stage dry sump pumps in dirt track racing.

By ensuring consistent oil delivery and reducing engine wear, these systems provide racers with the reliability and performance needed to succeed in the highly competitive environment of dirt track racing.

Conclusion and Recommendations

Throughout this blog post, we have delved into the intricacies of selecting the best 5 stage dry sump pump for dirt track racing.

The key factors discussed include performance, reliability, and compatibility with various engine setups.

By analyzing different brands and models, we have identified several top contenders in the market.

When considering a 5 stage dry sump pump, it is imperative to assess your specific racing needs.

The pump should not only enhance engine performance but also ensure consistent oil flow and pressure, crucial for maintaining engine health under demanding track conditions.

Brands like Peterson Fluid Systems, Barnes Systems, and Dailey Engineering have proven to be exceptional in providing high-quality, reliable pumps that meet these criteria.

Based on our analysis, the Peterson Fluid Systems 5 stage dry sump pump stands out due to its robust construction and superior performance.

Its modular design and ease of maintenance make it an excellent choice for both amateur and professional racers.

Similarly, Barnes Systems offers a range of pumps known for their durability and efficiency, making them a viable option for those seeking long-term reliability.

Additionally, Dailey Engineering’s pumps are highly regarded for their innovative design and adaptability to various engine configurations, offering racers the flexibility to fine-tune their setups.

However, it is crucial to consult with professionals or experienced racers to ensure the selected pump aligns with your engine specifications and racing conditions.

In conclusion, while there are several excellent 5 stage dry sump pumps available, the best choice depends on individual requirements and preferences.

We recommend thorough research and professional consultation to make an informed decision.

Investing in a high-quality dry sump pump can significantly enhance your dirt track racing performance.

ensuring you stay competitive and enjoy a smoother racing experience.

Share your thoughts on dry sump system . 🔥