In the world of UTVs, the pursuit of speed, power, and extreme terrain capability often takes center stage. But for any serious off-road enthusiast, there is one factor that should always be paramount: safety. The single most critical safety feature on your side-by-side is the Roll Over Protection System (ROPS), commonly known as the roll cage.

While every UTV comes equip with a factory ROPS, these are often design to meet minimum regulatory standards, not the demands of aggressive trail riding, rock crawling, or high-speed desert racing. For those who push their machines to the limit, upgrading to advanced roll cage protection systems is not just an option—it’s a necessity.

I’ve seen firsthand the difference a properly engineered roll cage can make. It’s the difference between a scary moment and a catastrophic accident. This guide will take you deep into the technology and engineering behind the unbreakable shell that protects you. We will break down the materials, the design principles, the industry standards, and the aftermarket upgrades that turn your UTV into a true fortress on wheels.

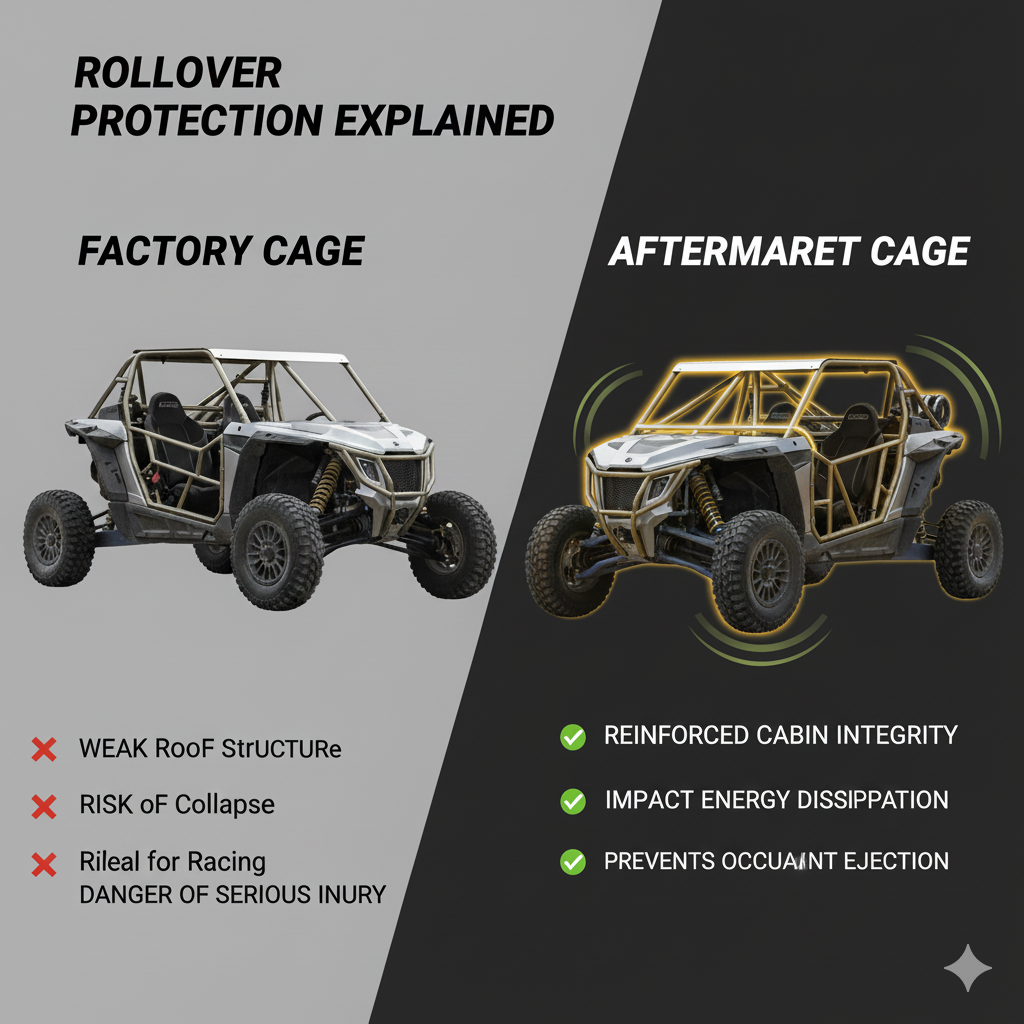

Phase 1: Understanding the Factory ROPS vs. Aftermarket Cages

Before investing in an upgrade, it’s vital to understand what your factory cage is design to do and where its limitations lie.

The Factory ROPS: Meeting Minimum Standards

The factory Roll Over Protection System (ROPS) is design to protect occupants in a low-speed, single-roll incident.

- Primary Goal: To prevent the roof from collapsing and crushing the occupants during a rollover.

- Construction: Typically made from mild steel tubing, often with thinner walls and fewer support points than an aftermarket cage.

- Limitation: Factory cages are generally not design to withstand multiple, high-energy impacts or the kind of violent, high-speed tumbles common in racing or extreme off-roading. They are a starting point, not the final word in protection.

The Aftermarket Advantage

Advanced roll cage protection systems from reputable aftermarket manufacturers are engineer for maximum occupant safety under extreme conditions.

- Superior Materials: They utilize stronger, lighter materials like Chromoly or high-grade DOM steel.

- Enhanced Geometry: They feature complex geometric patterns, additional cross-bracing, and more tie-in points to the chassis, creating a much more rigid and robust safety cell.

- Improved Visibility and Style: Many aftermarket cages are design with a lower profile and sleeker lines, improving the UTV’s aesthetics while often increasing the driver’s field of vision.

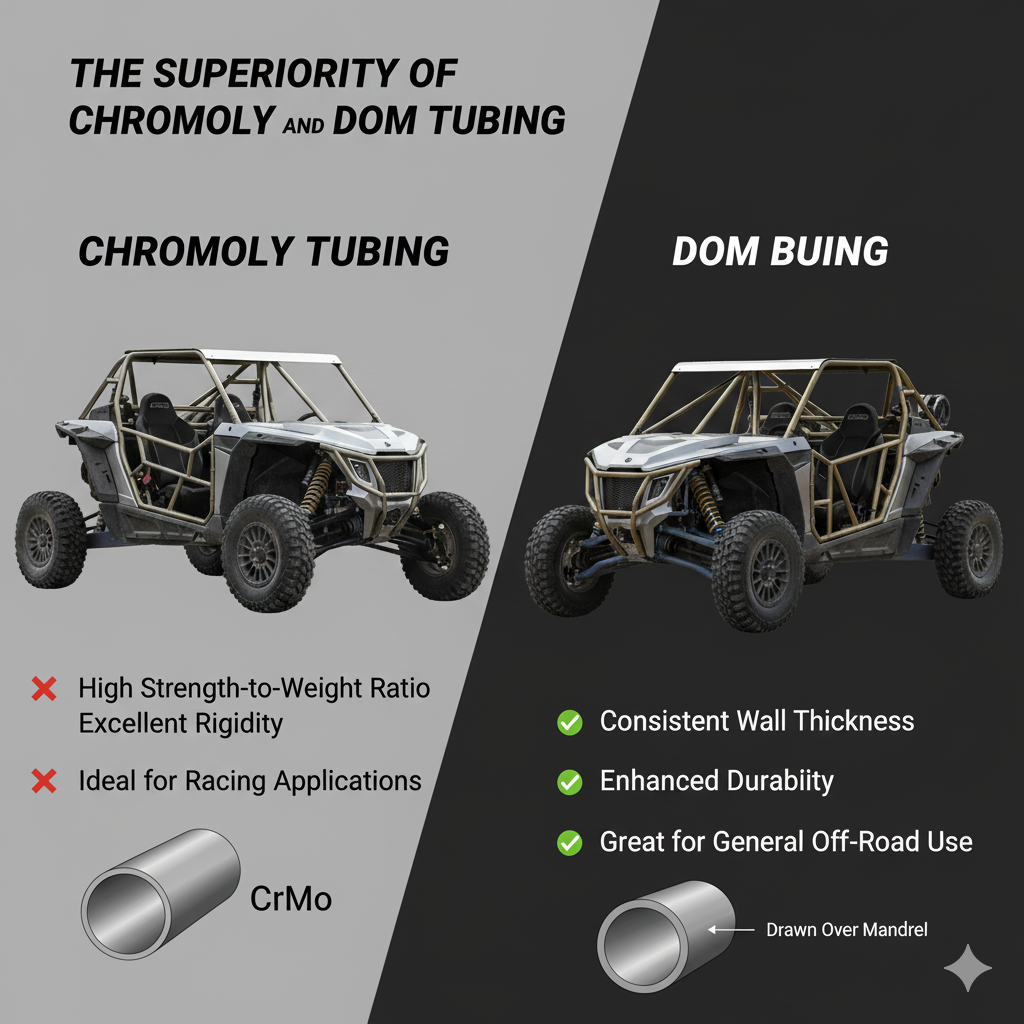

Phase 2: The Science of Strength—Tubing Materials

The material used in your roll cage is the single biggest factor determining its strength-to-weight ratio. The two primary materials in advanced roll cage protection systems are Drawn Over Mandrel (DOM) steel and Chromoly steel.

Drawn Over Mandrel (DOM) Steel

DOM is a type of seamless, cold-formed, electric resistance welded (ERW) steel tubing that has been processed further to smooth out the internal weld seam.

- Strength: DOM is significantly stronger than standard mild steel tubing, offering excellent yield and tensile strength.

- Cost and Weldability: It is more affordable than Chromoly and can be welded with standard MIG welding equipment, making it a popular choice for custom fabricators and enthusiasts.

- Weight: It is heavier than Chromoly for the same strength rating, meaning a DOM cage will add more weight to the UTV.

Chromoly (Chrome Molybdenum) Steel

Chromoly (specifically 4130 Chromoly) is a high-strength steel alloy known for its superior strength-to-weight ratio.

- Strength and Weight: Chromoly is stronger than DOM, allowing builders to use thinner wall tubing to achieve the same or greater strength. This results in a lighter overall cage, which is critical for performance.

- Cost and Weldability: It is more expensive than DOM and requires TIG welding by a skilled professional to maintain its strength properties, making it the material of choice for professional racing applications.

| Tubing Material | Strength-to-Weight Ratio | Cost | Welding Requirement | Ideal Application |

|---|---|---|---|---|

| DOM Steel | Good | Moderate | MIG (Easier) | Aggressive Trail Riding, Weekend Warriors |

| Chromoly Steel | Excellent | High | TIG (Specialized) | Professional Racing, Extreme Rock Crawling |

Phase 3: Design and Engineering Standards

A roll cage is only as good as its design and the standards it meets. For advanced roll cage protection systems, look for cages that meet or exceed established racing and safety standards.

The SFI and FIA Standards

While UTVs don’t have a single universal standard like NASCAR or Formula 1, many reputable aftermarket manufacturers design their cages to meet or exceed standards set by racing bodies.

- SFI Foundation: SFI standards are often references in off-road racing. A cage built to SFI specifications has been engineer to withstand specific loads and impacts, ensuring a high level of safety.

- FIA (Fédération Internationale de l’Automobile): FIA standards are the global benchmark for motorsports safety. Cages built to these specs are generally considered the gold standard for protection.

Essential Design Features

Beyond the material, the geometry of the cage is crucial for distributing impact forces away from the occupants.

- Gussets and Cross-Bracing: Look for cages with gussets (triangular plates) at critical joints and extensive cross-bracing (X-patterns) in the roof and rear sections. This prevents the cage from deforming under load.

- Tie-In Points: The cage should be securely tied into the strongest points of the UTV chassis, often using specialized mounting plates that distribute the load across a wider area.

- Intrusion Bars: These are horizontal bars placed across the door openings and sometimes across the front windshield area. They prevent foreign objects (like tree limbs or rocks) from entering the cab during a rollover or collision.

Phase 4: Beyond the Cage—Integrated Protection Systems

An advanced roll cage protection system is part of a larger safety ecosystem. The cage provides the structure, but other components ensure the occupants remain secure within that structure.

1. Harnesses and Seats

The best cage in the world is useless if the occupants are not properly restrained.

- Four- or Five-Point Harnesses: Upgrading from the factory three-point seatbelt to a secure harness is non-negotiable. The harness keeps the driver and passengers firmly planted in their seats, preventing them from being tossed around inside the cage during a rollover.

- Suspension Seats: High-quality suspension seats work in tandem with the harness to absorb vertical impacts and keep the rider comfortable and secure.

2. Doors and Nets

- Full Doors: Aftermarket full doors offer significantly more protection than the factory half-doors or nets, preventing limbs from exiting the vehicle during a roll.

- Window Nets: For racing or extreme conditions, window nets are mandatory. They prevent arms and heads from being thrown outside the cage, which is a common cause of serious injury in rollovers.

3. Roof and Windshield

- Aluminum or Polycarbonate Roofs: A strong roof, often made of aluminum or thick polycarbonate, protects against debris and helps the cage slide rather than dig in during a roll.

- Safety Glass Windshields: While not part of the cage structure, a laminated safety glass windshield offers superior protection from dust, debris, and objects compared to polycarbonate.

Conclusion: The Investment in Peace of Mind

The decision to upgrade to advanced roll cage protection systems is the most important safety investment you can make in your UTV. It is a commitment to yourself, your passengers, and the longevity of your off-road adventures.

Whether you choose the robust strength of DOM or the lightweight performance of Chromoly, the key is to select a cage from a reputable manufacturer that prioritizes engineering and safety standards. Don’t settle for a cage that simply looks good; choose one that is built to save lives.

The trail is calling, and with an unbreakable shell protecting you, you can answer that call with confidence and peace of mind.

Ride hard, ride safe, and always invest in protection!

References

[1] UTV Windshields and Accessories – Essential Guide to UTV Rollover Protection Systems (ROPS)

[2] UTV Speed – Understanding Roll Cages for Your Utility Vehicle

[3] Industrial Metal Supply – Chromoly vs. DOM Tubing

[4] Side By Side Fury – Best Aftermarket ATV Safety Cages For Ultimate Protection

[5] UTV Guide – UTV Roll Cages