The quest for sustainability in the automotive world has reached the rugged terrain of the UTV market.

For too long, the focus has been solely on the performance and durability of materials, often overlooking their environmental footprint.

Today, a new generation of engineers and designers is proving that sustainable materials in UTV manufacturing can deliver both exceptional strength and ecological responsibility.

This shift is driven by consumer demand, tightening regulations, and a growing understanding of the environmental cost associated with traditional manufacturing processes.

The goal is to create a UTV that is not only built to last but also built with the planet in mind, embodying the spirit of responsible adventure.

The Embodied Energy Challenge: Reducing the Carbon Debt

Every product carries an “embodied energy,” which is the sum of all energy required to produce it, from raw material extraction to final assembly.

In UTV manufacturing, this energy is substantial, particularly in the production of metals and plastics, contributing a significant “carbon debt” to the vehicle’s lifecycle [1].

The move toward sustainable materials is fundamentally an effort to reduce this embodied energy and the associated carbon emissions.

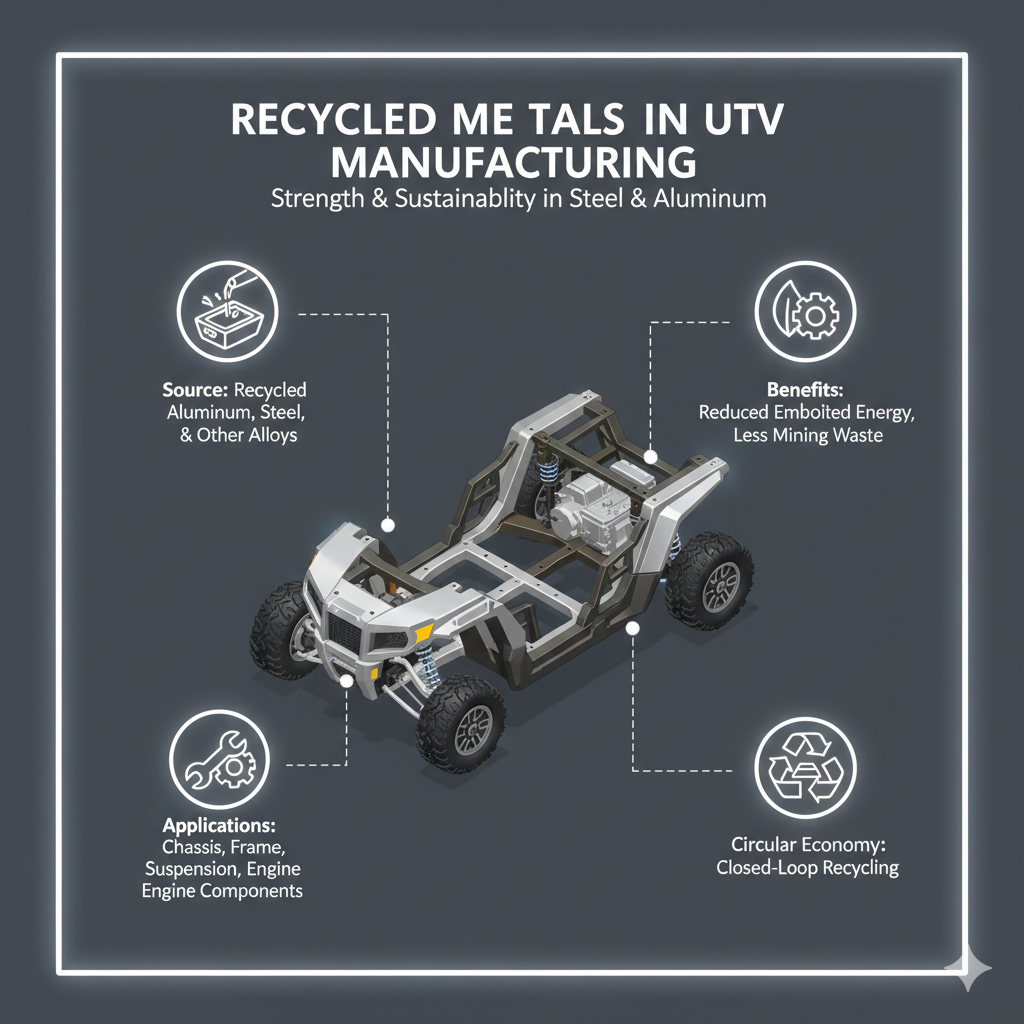

The Power of Recycled Metals: Aluminum and Steel

Aluminum and steel are the backbone of any UTV chassis and frame, providing the necessary structural integrity and safety.

The primary production of aluminum is notoriously energy-intensive, requiring vast amounts of electricity to smelt the ore.

However, recycling aluminum requires up to 95% less energy than producing primary aluminum, making the use of recycled content a massive win for sustainability [2].

Manufacturers are increasingly specifying high-grade recycled aluminum alloys for non-critical structural components and body panels, ensuring performance is not compromised.

Similarly, the use of recycled steel, which also offers significant energy savings, is becoming standard practice in the industry, often sourced from end-of-life vehicles.

The challenge lies in maintaining the purity and strength of these recycled alloys, which requires sophisticated sorting and processing technologies to ensure the material meets the rigorous safety and performance standards of off-road vehicles.

Bioplastics and Bio-Composites: A Renewable Future

Plastics are ubiquitous in UTVs, used for everything from dashboards and fenders to interior trim, and the industry is actively exploring alternatives to petroleum-based plastics.

Bioplastics, derived from renewable biomass sources such as corn starch, sugarcane, or cellulose, can significantly reduce the reliance on fossil fuels and lower the carbon footprint of plastic components [3].

One promising material is Polypropylene (PP) derived from renewable sources, which offers the same durability and impact resistance as its traditional counterpart but with a much lower carbon footprint.

Another area of innovation is the use of natural fiber composites, where fibers like flax, hemp, or kenaf are used to reinforce polymers, creating components that are lighter, offer excellent vibration damping, and have a more sustainable end-of-life profile.

These natural fibers are often sourced from agricultural waste streams, providing a dual benefit of reducing waste and creating a high-performance, sustainable material [10].

The challenge with bioplastics is ensuring they can withstand the extreme temperatures and UV exposure of the off-road environment without premature degradation, a hurdle that is being rapidly overcome through advanced chemical stabilization.

Advanced Material Applications in UTV Components

The application of sustainable materials is moving beyond simple body panels to core functional components, driving both performance and environmental gains simultaneously.

Sustainable Interior and Trim

The UTV interior, while designed for ruggedness, still presents opportunities for sustainable material use that enhance durability and comfort.

Seat fabrics and upholstery are being developed from recycled polyethylene terephthalate (rPET), which is derived from recycled plastic bottles, offering a durable, water-resistant, and UV-stable solution [4].

Furthermore, the use of natural rubber and soy-based foams for seating and insulation reduces the reliance on synthetic, petroleum-derived materials, contributing to better air quality within the cab.

The focus here is on creating a cabin that is both comfortable and environmentally conscious, without sacrificing the ability to withstand harsh off-road conditions.

Even the dyes and pigments used in interior plastics are being scrutinized, with a shift toward mineral-based and natural colorants to reduce the use of heavy metals and other toxic substances.

Lightweighting with Carbon Fiber Alternatives

While traditional carbon fiber offers exceptional strength-to-weight ratios, its production is energy-intensive and its end-of-life disposal is challenging.

Researchers are developing bio-based carbon fiber alternatives, such as those derived from lignin, a byproduct of the paper industry, to address this challenge [5].

These materials aim to achieve similar performance characteristics with a fraction of the environmental cost, offering a sustainable path for high-performance components like suspension arms and roll cages.

The ultimate goal is to achieve the performance benefits of lightweighting while simultaneously reducing the manufacturing footprint.

Another promising area is the use of basalt fiber composites, which are made from melted volcanic rock, offering a high-strength, non-toxic, and more easily recyclable alternative to traditional glass or carbon fiber composites [11].

Sustainable Lubricants and Fluids

The materials used in a UTV extend beyond the solid components to the fluids that keep the machine running.

The shift toward bio-based lubricants and hydraulic fluids, derived from vegetable oils and other renewable sources, is a critical step in reducing the environmental impact of accidental fluid leaks on the trail [12].

These fluids are often biodegradable and less toxic than their petroleum-based counterparts, offering a layer of environmental protection in sensitive ecosystems.

Manufacturers are also exploring the use of closed-loop cooling systems that utilize non-toxic, long-life coolants, further minimizing the risk of environmental contamination.

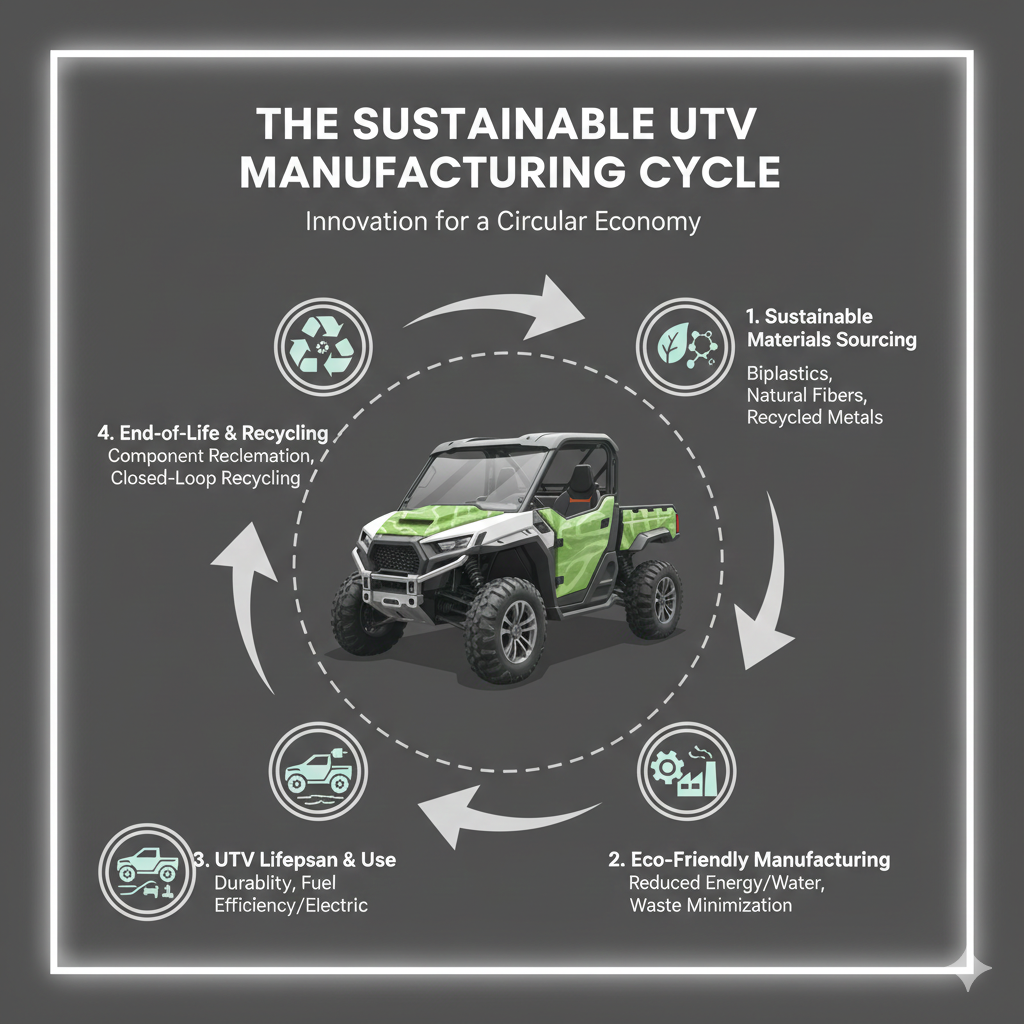

The Circular Economy in UTV Manufacturing

True sustainability requires a shift from a linear “take-make-dispose” model to a circular economy, where materials are kept in use for as long as possible, minimizing waste and maximizing resource efficiency.

UTV manufacturers are beginning to design vehicles with disassembly and material recovery in mind, a philosophy known as Design for Disassembly.

Design for Disassembly (DfD)

Design for Disassembly (DfD) is a manufacturing philosophy that prioritizes the ease with which a product can be taken apart at the end of its life, facilitating the recovery of valuable materials.

This involves using fewer types of materials, minimizing the use of permanent fasteners like welding, and clearly labeling components with their material type for easy sorting and recycling [6].

A UTV designed for disassembly ensures that high-value materials, such as rare earth elements in electric motors or advanced composites, can be efficiently recovered and reintroduced into the manufacturing stream, reducing the need for virgin resources.

This design approach also simplifies the repair process, extending the lifespan of the vehicle and further reducing its overall environmental footprint.

Closed-Loop Recycling Systems and Industrial Symbiosis

Leading manufacturers are establishing closed-loop recycling systems, where the waste generated during the manufacturing process is collected and fed directly back into the production line.

For example, excess aluminum scrap from stamping operations is melted down and recast into new components,

eliminating the need for external sourcing and reducing transportation emissions [7].

This commitment to internal recycling minimizes waste and ensures that every material input is maximized for its full potential,

creating a more efficient and responsible manufacturing process.

The concept of industrial symbiosis is also being explored,

where the waste stream of one UTV manufacturer becomes a valuable input for another industry,

such as using waste plastics for construction materials, creating a broader regional circular economy.

The Future of UTV Materials: Beyond the Horizon

The research and development pipeline for sustainable materials is constantly yielding new and exciting possibilities for the UTV industry,

promising to further decouple performance from environmental impact.

Self-Healing Polymers and Smart Materials

The next frontier in UTV materials includes self-healing polymers,

which can automatically repair minor scratches and cracks in body panels,

extending the lifespan of components and reducing the need for replacement parts [8].

Furthermore, smart materials that can change their properties in response to environmental conditions,

such as temperature or impact,

could lead to more durable and adaptive UTV designs, further enhancing longevity and reducing waste.

For example, a smart material could change its stiffness in response to impact,

absorbing energy more effectively and preventing catastrophic failure,

thereby extending the life of the component and reducing the need for replacement.

The Role of Additive Manufacturing and Material Customization

Additive manufacturing, or 3D printing, is inherently more sustainable than traditional subtractive manufacturing methods,

as it allows for the creation of complex parts with minimal material waste.

As 3D printing materials become stronger and more diverse,

UTV manufacturers can use this technology to produce customized,

on-demand parts from sustainable powders and filaments,

further reducing inventory and logistics-related emissions [9].

This technology also enables the use of material customization,

where the material properties can be varied within a single component,

placing high-strength, recycled materials only where they are needed most,

optimizing both performance and sustainability.

The Consumer’s Influence: Driving Material Change

The ultimate success of sustainable materials in UTV manufacturing rests on the consumer’s willingness to embrace and demand these eco-conscious choices.

Transparency and Certification

Consumers are increasingly looking for transparency regarding the environmental footprint of the products they purchase.

Manufacturers can respond by providing clear, verifiable information on the percentage of recycled content,

the source of bio-based materials, and the energy used in production.

The adoption of third-party certifications, such as those for sustainable forestry or recycled content,

provides an independent verification of these claims, building trust and driving market demand for sustainable UTVs [13].

Durability as the Ultimate Sustainability Metric

The most sustainable material is one that lasts the longest, regardless of its initial source.

By focusing on materials that offer exceptional durability and longevity,

manufacturers inherently reduce the need for replacement parts and the associated manufacturing footprint.

This philosophy of “durability as sustainability” is a powerful selling point that aligns the interests of the consumer—who wants a rugged,

reliable UTV—with the interests of the planet.

The integration of sustainable materials into UTV manufacturing is a powerful testament to the industry’s commitment to a greener future.

It is a complex, ongoing process that requires continuous innovation,

but the result is a vehicle that is a true reflection of the adventurous spirit:

powerful, resilient, and respectful of the natural world it explores.

References

[1] European Commission. (n.d.). Embodied Energy in Products. Retrieved from [URL for European Commission resource]

[2] The Aluminum Association. (n.d.). Aluminum Recycling Facts. Retrieved from [URL for Aluminum Association resource]

[3] Bioplastics Magazine. (n.d.). Bioplastics in Automotive Applications. Retrieved from [URL for Bioplastics Magazine article]

[4] Sustainable Composites. (n.d.). Natural Fiber Composites in Vehicle Interiors. Retrieved from [URL for Sustainable Composites resource]

[5] Advanced Materials Research. (n.d.). Lignin-Based Carbon Fiber Development. Retrieved from [URL for Advanced Materials Research paper]

[6] Ellen MacArthur Foundation. (n.d.). Design for Disassembly in the Circular Economy. Retrieved from [URL for Ellen MacArthur Foundation resource]

[7] GlobalData. (n.d.). Sustainable Materials Reshape the Auto Industry. Retrieved from [URL for GlobalData report]

[8] ScienceDirect. (n.d.). Self-Healing Polymers for Automotive Applications. Retrieved from [URL for ScienceDirect article]

[9] Additive Manufacturing Magazine. (n.d.). Sustainability Benefits of 3D Printing. Retrieved from [URL for Additive Manufacturing Magazine article]