For off-road enthusiasts, the thrill of navigating challenging terrains in a Utility Terrain Vehicle (UTV) is unmatched.

These rugged machines are built for adventure, but their performance is constantly being pushed to new limits.

Whether it’s conquering steep inclines, enduring harsh impacts, or simply seeking a more agile ride, the demand for lighter, stronger, and more efficient UTVs is ever-growing.

This is where the magic of lightweight composite materials comes into play, revolutionizing how UTVs are designed, built, and experienced.

Imagine a UTV that can accelerate faster, handle more precisely, and withstand the brutal punishment of extreme off-roading, all while consuming less fuel.

This isn’t a futuristic dream; it’s the present reality being shaped by advanced composites.

These materials offer a compelling alternative to traditional metals, promising a future where UTVs are not just tough, but also incredibly nimble and sustainable.

What Exactly Are Lightweight Composites?

At their core, lightweight composite materials are engineered substances made from two or more constituent materials with significantly different physical or chemical properties.

When combined, they produce a material with characteristics superior to those of the individual components.

For UTVs, this typically means a matrix (often a resin like epoxy or polyester) reinforced with high-strength fibers such as carbon or fiberglass [1].

The beauty of composites lies in their ability to be tailored Engineers can select specific fibers and matrices,

and arrange them in precise orientations, to achieve desired properties like exceptional strength-to-weight ratios, stiffness, and impact resistance.

This customization is crucial for UTV applications, where components face a diverse range of stresses and environmental conditions.

Why Composites are a Game-Changer for UTVs

The advantages of integrating lightweight composites into UTV manufacturing are profound and far-reaching.

They address several critical performance and operational aspects that traditional materials often struggle with.

1. Unrivaled Strength-to-Weight Ratio

One of the most significant benefits is the dramatic reduction in weight without compromising structural integrity.

For instance, **carbon fiber** can be five times stronger and significantly lighter than steel [1].

This superior strength-to-weight ratio directly translates to enhanced performance.

A lighter UTV means less inertia, allowing for quicker acceleration, more responsive braking, and improved maneuverability on tight trails.

2. Enhanced Fuel Efficiency

Physics dictates that a lighter vehicle requires less energy to move.

By shedding pounds through composite construction, UTVs can achieve better fuel economy.

This is a win-win: it reduces operational costs for owners and lessens the environmental footprint, making off-roading a more sustainable pursuit [1].

3. Superior Durability and Impact Resistance

Off-road environments are unforgiving. Rocks, debris, and unexpected impacts are part of the territory.

Composites, particularly those with advanced fiber reinforcement, offer exceptional durability.

They are less prone to deformation, cracking, or breaking under extreme conditions compared to many metals.

This inherent toughness means components like skid plates, body panels, and even wheels can better absorb impacts and resist damage, leading to a longer lifespan for the vehicle and reduced maintenance [1].

4. Corrosion Resistance

Unlike metals, many composite materials do not corrode.

This is a critical advantage for UTVs that are frequently exposed to moisture, mud, salt, and other corrosive elements.

Components made from composites maintain their structural integrity and aesthetic appeal over time, free from rust and degradation [1].

5. Design Flexibility and Innovation

The moldable nature of composite materials allows for complex and aerodynamic designs that are often impossible or cost-prohibitive with traditional manufacturing methods.

This design versatility opens doors for innovative UTV aesthetics and functional improvements, enabling engineers to optimize shapes for better airflow, rider comfort, and component integration [1].

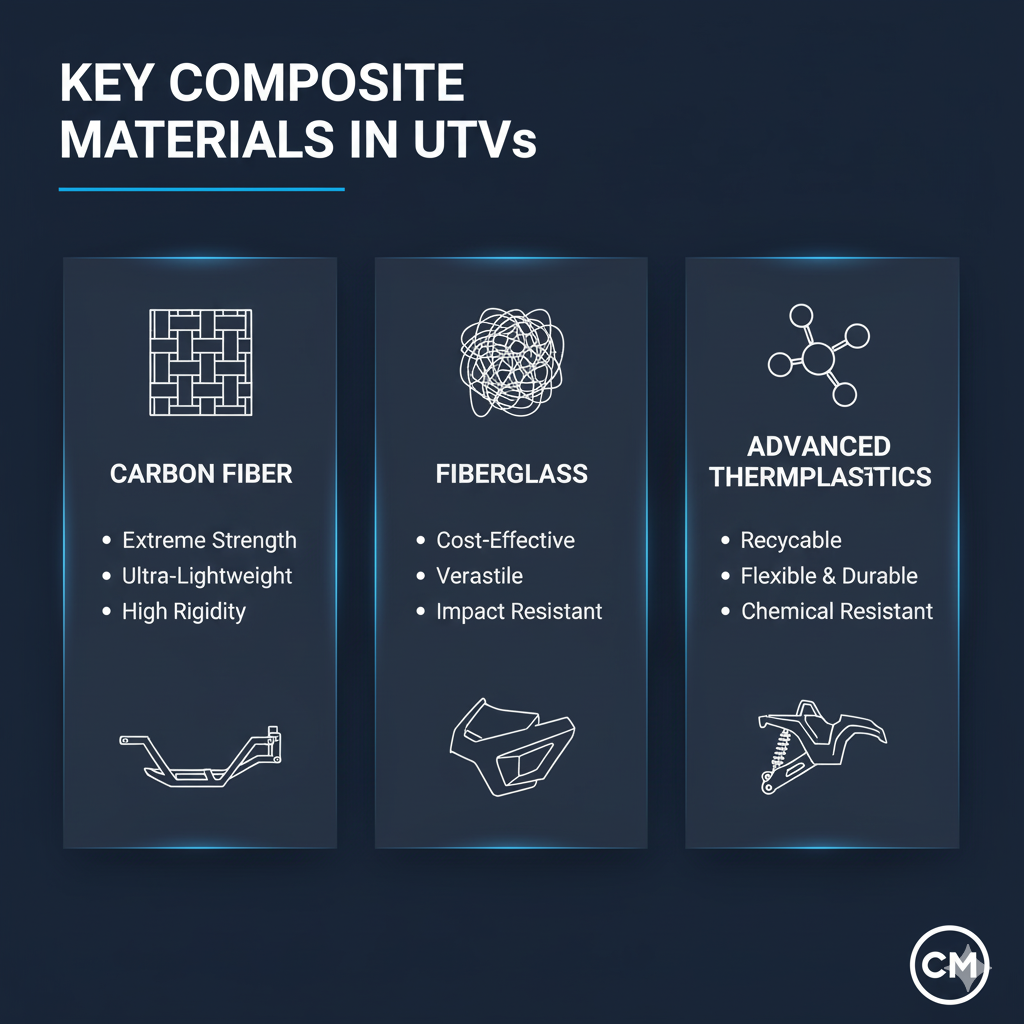

Key Lightweight Composite Materials in UTV Applications

Several types of composite materials are making their mark in the UTV world, each with unique properties suited for different applications.

Carbon Fiber Reinforced Polymer (CFRP)

Carbon fiber is the superstar of lightweight composites.

Known for its exceptional strength, stiffness, and incredibly low weight, CFRP is increasingly found in high-performance UTV components.

From chassis elements and suspension arms to body panels and aftermarket accessories, carbon fiber offers an unmatched performance advantage.

Its sleek, high-tech appearance is also a bonus for enthusiasts looking to customize their rides [2].

Companies like HiPer Technology have leveraged carbon fiber composites to create ATV and UTV wheels that are significantly lighter than their aluminum counterparts, without sacrificing durability.

These wheels are engineered to handle extreme terrain, improving handling and responsiveness [2, 3].

Similarly, brands like FourWerx Carbon and Super Comp specialize in carbon fiber parts such as hoods, consoles, door latches, and even full body kits for popular UTV models, showcasing the material’s versatility and aesthetic appeal [4, 5].

Fiberglass Reinforced Polymer (FRP)

Fiberglass, while not as strong or light as carbon fiber, offers an excellent balance of performance and cost-effectiveness.

It’s versatile, corrosion-resistant, and widely used in various UTV components, including body panels, fenders, and some structural elements.

Fiberglass is a popular choice for manufacturers looking to reduce weight and improve durability without the premium cost associated with carbon fiber [1, 6].

Advanced Thermoplastics

Thermoplastic composites are gaining traction due to their inherent toughness, faster processing times, and recyclability.

Unlike thermoset composites (like traditional epoxy-based carbon fiber), thermoplastics can be reheated and reshaped,

offering manufacturing advantages and potential for repair and recycling.

Oribi Composites, for example, has developed high-performance off-road UTV wheels using advanced thermoplastic composite materials that are 50% lighter than aluminum, yet incredibly strong and durable [3].

This innovation highlights the potential for thermoplastics to deliver significant weight savings and enhanced performance in demanding UTV applications.

Hybrid Composites

Some manufacturers are also exploring hybrid composite options, combining the best features of different materials.

For instance, composite skid plates might blend the impact resistance of HDPE (High-Density Polyethylene) with the rigidity of other fibers, offering a balanced solution for critical undercarriage protection [7].

This approach allows for optimized material selection based on specific performance requirements and cost considerations.

The Future of UTVs: Lighter, Stronger, Faster

The integration of lightweight composite materials is not just a trend; it’s a fundamental shift in UTV design and manufacturing.

As technology advances, we can expect to see even more innovative applications of these materials, leading to UTVs that are:

More Agile and Responsive: Lighter vehicles mean better handling and a more engaging driving experience.

More Durable: Enhanced resistance to impacts and corrosion translates to longer component life and reduced maintenance.

More Fuel-Efficient: Contributing to lower running costs and a smaller environmental footprint.

More Customizable: The design flexibility of composites allows for a wider range of aftermarket parts and personalization options.

The journey of UTVs from utilitarian workhorses to high-performance recreational vehicles has been remarkable.

Lightweight composite materials are undoubtedly at the forefront of this evolution, promising an exciting future for off-road adventures where limits are continually pushed, and performance is redefined.

References

[1] True Composites. (2025, March 4). *How to Make Ultra-Lightweight Composite Structures for Boats and RVs*. Retrieved from []()

[2] HiPer Technology. *Shop ATV Wheels – Carbon Fiber ATV Wheels*. Retrieved from [

[3] Moore, S. (2021, December 3). *Thermoplastic Wheel Takes the Rough Road*. PlasticsToday. Retrieved from []()

[4] FourWerx Carbon. *Carbon Fiber and Titanium Products*. Retrieved from

[5] Super Comp. *Super Comp Carbon Fiber Parts | UTV & Harley Parts*. Retrieved from []()

[6] FiberwerX. *Fiberglass & Carbon Fiber Products*. Retrieved from

[7] Vessel Powersports. (2025, February 10).

*A Complete Guide to Honda UTV Skid Plates: The Ultimate Protection for Off-Roading Adventures*.