It’s the end of an amazing day on the trails. As the sun sets, you’re loading your UTV onto the trailer for the journey home. But first, you face that familiar frustration – removing your whip lights.

You dig through your toolbox for the right wrench, struggle with mud-caked bolts, and carefully set aside the expensive LED whips, hoping they won’t get damaged during transport.

This ritual adds 15 minutes to your already long day, and you know you’ll have to reverse the entire process when you arrive at your next riding destination.

If this scenario sounds all too familiar, you’re not alone.

Whip lights and safety flags are essential accessories for most UTV enthusiasts – providing crucial visibility in dunes, marking your position to other riders, and often required by law at many riding locations.

But the traditional mounting systems create a constant hassle that dampens the end of every ride.

Enter the quick disconnect whip mount – an ingenious solution that transforms this tedious process into a simple, tool-free operation that takes seconds rather than minutes.

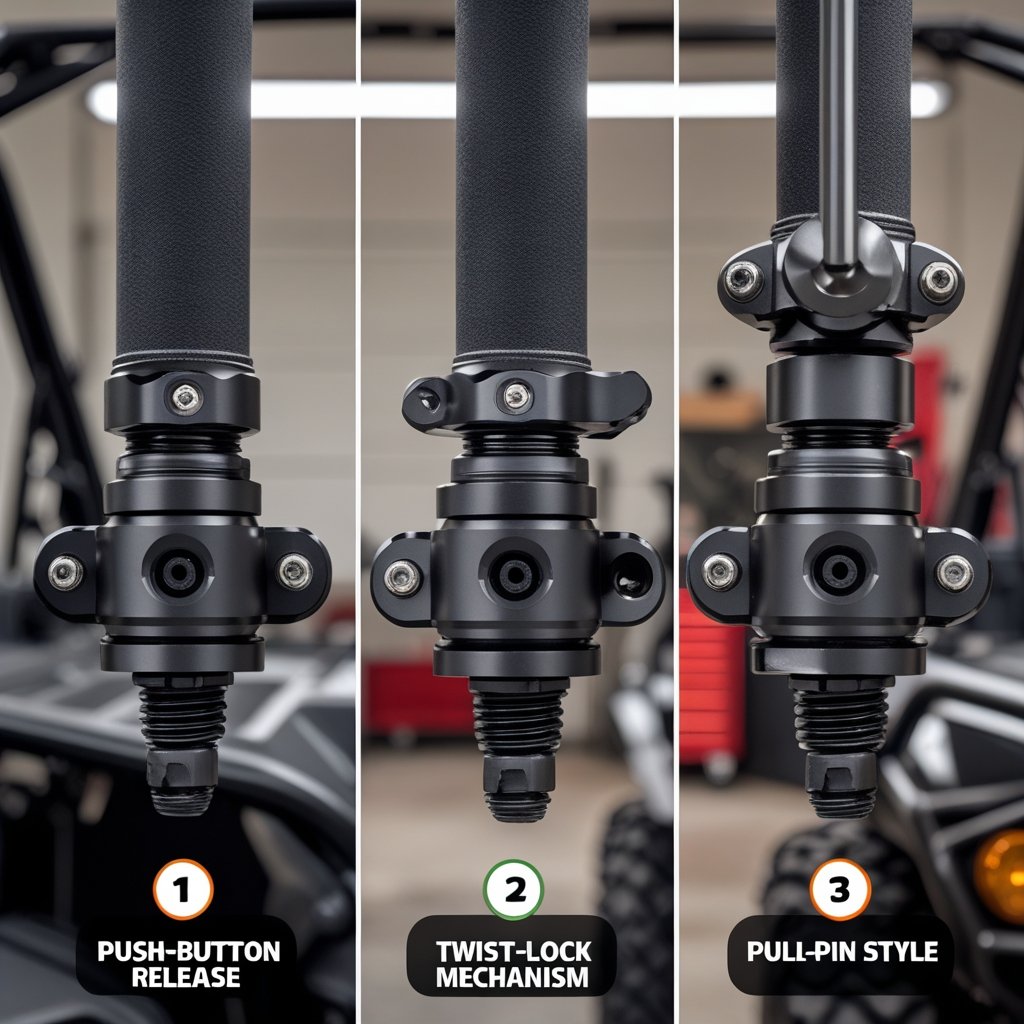

These innovative mounts allow you to install or remove whips with a simple twist, click, or pull, eliminating the need for tools while providing secure attachment during even the most aggressive rides.

In this comprehensive guide, we’ll explore everything you need to know about quick disconnect whip mounts – from the different types and benefits to installation tips and top product recommendations.

Whether you’re tired of the removal ritual or looking to protect your investment in premium LED whips, this guide will help you find the perfect solution for your riding style.

Why Every UTV Owner Needs a Quick Disconnect Whip Mount

Traditional whip mounts serve their basic purpose, but quick disconnect whip mounts offer significant advantages that make them worth considering for any serious UTV enthusiast:

Time-Saving Convenience

The most immediate benefit is pure convenience. Rather than spending 10-15 minutes removing whips with wrenches and socket sets, quick disconnect systems allow you to remove or install whips in seconds – often with just a twist, pull, or push of a button.

This time savings adds up, especially for riders who frequently transport their UTVs between riding locations.

For weekend warriors with limited riding time, those extra minutes matter. When you’re trying to get on the trail quickly or pack up after a long day, the last thing you want is another time-consuming task.

Quick disconnect whip mounts eliminate this hassle, letting you focus on the ride rather than the preparation.

Protection for Expensive Whip Lights

Modern LED whip lights represent a significant investment, with premium options costing $200 or more per whip. These delicate electronic components can be easily damaged during transport if left attached to your UTV.

Low garage clearances, trailer loading, and highway travel all present risks to exposed whips.

Quick disconnect whip mounts make it practical to remove and safely store your whips whenever you’re not actively riding.

This protection extends the lifespan of your lighting investment and prevents the frustration of arriving at your destination with damaged equipment.

Simplified Transport and Storage

Many UTV owners face clearance challenges when transporting their vehicles. Whether you’re loading into an enclosed trailer, storing in a garage with limited ceiling height, or navigating low-hanging obstacles, tall whips often need to be removed.

With traditional mounts, these clearance issues often force a choice between time-consuming removal or risking damage.

Quick disconnect whip mounts eliminate this dilemma, making it practical to remove whips whenever necessary without adding significant time to your preparation.

Enhanced Safety and Compliance

Many riding areas require safety flags or whips of specific heights for visibility. However, these requirements can vary between locations.

What’s mandatory in dune environments might be unnecessary or even problematic on tight forest trails with low-hanging branches.

Quick disconnect whip mounts allow you to easily adapt to different riding environments and regulations.

You can quickly swap between tall dune whips and shorter trail options, or remove them entirely when navigating particularly tight spaces, all without tools or significant downtime.

Versatility for Different Riding Environments

Beyond regulatory compliance, different riding environments benefit from different whip setups. Dune riding typically calls for tall, highly visible whips, while trail riding might benefit from shorter, more durable options that won’t catch on branches.

The ease of swapping whips with a quick disconnect system means you can optimize your setup for each environment without compromise.

Some riders even keep multiple whip options in their gear bag, changing them out based on conditions or time of day.

Understanding Quick Disconnect Whip Mount Technology

Before diving into specific products and installation, it’s helpful to understand the different types of quick disconnect whip mount systems available:

Basic Types of Quick Disconnect Systems

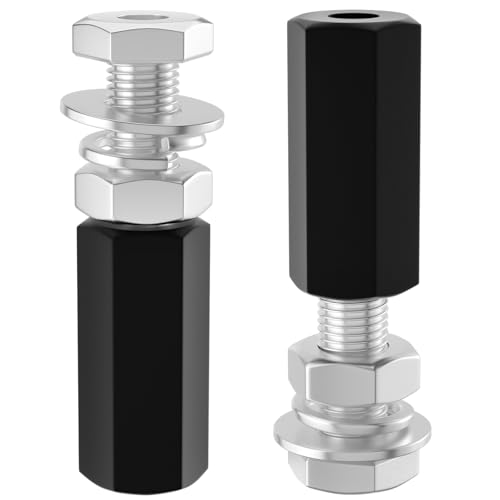

Tool-Free Designs: The most basic quick disconnect systems replace traditional bolts with hand-tightenable knobs or levers. These systems still require you to fully remove the mounting hardware, but eliminate the need for tools.

Folding Mechanisms: These innovative mounts allow whips to fold down for transport or storage without removing them entirely. Typically secured with quick-release pins, they provide a convenient middle ground between permanent mounting and full removal.

Quick-Release Pins: Many premium systems use spring-loaded or plunger-style pins that lock the whip securely in place but can be removed in seconds when needed. These pins often feature safety mechanisms to prevent accidental release during aggressive riding.

Spring-Loaded Options: Some systems incorporate spring tension to hold whips in receivers, allowing them to be pulled out when needed but remaining secure during normal operation. These are particularly popular for flag whips rather than heavier LED options.

Material and Construction Considerations

Stainless Steel vs. Aluminum: Most quality quick disconnect whip mounts are constructed from either stainless steel or aluminum. Stainless offers superior durability and corrosion resistance, while aluminum provides weight savings and is often less expensive.

Corrosion Resistance: For riders in coastal areas or regions where UTVs are exposed to salt (either from ocean environments or winter road treatments), corrosion resistance is crucial. Look for anodized aluminum or marine-grade stainless steel for maximum longevity.

Weight Factors: While the weight difference between mount types is minimal, it can be a consideration for performance-focused riders. Aluminum mounts typically weigh 30-50% less than comparable stainless steel options.

Durability in Extreme Conditions: The best mounts feature overbuilt construction that can withstand the vibration, impacts, and environmental exposure common in off-road environments. Quality systems use thick materials, precision machining, and secure locking mechanisms.

Compatibility Factors

Universal vs. Vehicle-Specific Mounts: Some quick disconnect whip mounts are designed for universal fitment, while others are engineered specifically for certain UTV models. Vehicle-specific options typically offer cleaner installation and better integration but limit future flexibility if you change vehicles.

Whip Diameter Considerations: Not all whips have the same base diameter. Most mounts accommodate standard 1/2″ whip bases, but verify compatibility if you’re using specialty whips or particularly large LED models.

Mounting Location Options: Common mounting locations include roll cages, bed rails, and specialized mounting points on some UTV models (like Polaris Lock & Ride systems). Different quick disconnect systems are optimized for different mounting locations.

LED Wiring Accommodation: For LED whips, electrical connections are a crucial consideration. Quality quick disconnect whip mounts include provisions for wiring, often with quick-disconnect electrical connectors that separate when the whip is removed.

Key Benefits of Quick Disconnect Whip Mounts

The advantages of quick disconnect whip mounts extend far beyond simple convenience:

Practical Advantages

No Tools Required: The defining feature of these systems is tool-free operation. Even with gloves on or in challenging weather conditions, whips can be quickly removed or installed without searching for the right wrench size.

Seconds vs. Minutes: What typically takes 5-15 minutes with traditional mounts can be accomplished in 15-30 seconds with a quality quick disconnect system. This time savings is particularly valuable at the end of long riding days or in adverse weather conditions.

Reduced Risk of Thread Stripping: Frequent removal and reinstallation of traditionally mounted whips can lead to stripped threads in aluminum mounting points. Quick disconnect systems eliminate this risk by reducing the number of threaded connections that are regularly disturbed.

Protection for Expensive Whip Lights: Beyond physical damage during transport, removing LED whips when not in use protects them from prolonged UV exposure, moisture intrusion, and potential theft. This protection significantly extends their operational lifespan.

Transport Benefits

Trailer Clearance Issues Solved: Many enclosed trailers have insufficient clearance for installed whips, forcing removal. Quick disconnect whip mounts make this process fast enough that it’s no longer a significant inconvenience.

Garage Storage Simplified: Home garage storage often presents similar clearance challenges. Quick disconnect systems allow for easy removal when parking at home, eliminating the risk of damaged whips or garage infrastructure.

Prevents Damage During Transport: Even in trailers with adequate clearance, highway travel creates significant wind force on tall whips. Removing them for transport eliminates this stress and prevents premature failure of whips or mounts.

Theft Deterrence: LED whips represent an attractive target for theft at trailheads or overnight camping locations. The ability to quickly remove and secure these expensive accessories provides peace of mind when your UTV must be left unattended.

Riding Flexibility

Quick Adaptation Between Environments: Different riding environments call for different whip setups. Dunes benefit from tall, highly visible whips, while wooded trails may require shorter options or no whips at all. Quick disconnect systems make these transitions simple.

Easy Switching Between Whip Types: Many riders own multiple whip styles – perhaps standard safety flags for day use and LED options for night riding. Quick disconnect whip mounts allow for easy swapping based on conditions or riding plans.

Trail-to-Dune Versatility: Riders who enjoy both trail and dune environments often face different requirements and challenges in each setting. Quick disconnect systems facilitate rapid adaptation to each environment’s needs.

Weather Adaptation: In some conditions – particularly high winds – tall whips can actually create handling challenges. The ability to quickly remove or swap to shorter options allows adaptation to changing weather conditions.

Installation Guide: Setting Up Your Quick Disconnect Mount

Installing a quick disconnect whip mount is within the capabilities of most UTV owners with basic tools and mechanical knowledge. Here’s a streamlined approach:

Choosing the Right Location

Common Mounting Points: Popular locations include roll cage tubes, bed rails, specialized mounting tabs, and factory mounting points on some UTV models. The ideal location provides good visibility while minimizing interference with operation and cargo.

Clearance Considerations: Ensure your chosen location allows the whip to stand straight without contacting roll cages, roofs, or other accessories. Also consider clearance for folding mechanisms if your mount includes this feature.

Visibility Factors: The primary purpose of whips is visibility to other riders. Mount locations should allow your whip to be seen from all directions, particularly from behind and when cresting dunes.

Stability Requirements: Whips experience significant forces during high-speed riding and from wind resistance. Mount to substantial structural components that can withstand these forces without flexing.

Tools and Materials Needed

- Basic wrench or socket set (for initial installation only)

- Drill with appropriate bits (if mounting to locations without existing holes)

- Thread locker (medium strength recommended)

- Electrical tape and/or heat shrink tubing (for LED whip installations)

- Zip ties for securing wiring

- Anti-seize compound (for stainless hardware in aluminum mounting points)

Step-by-Step Installation

- Preparation:

- Identify your mounting location

- Gather all necessary tools and materials

- Ensure you have all mounting hardware

- For LED whips, plan your wiring route

- Mounting Process:

- Attach the base mount to your chosen location

- Apply thread locker to threads

- Tighten to manufacturer’s specifications

- Verify the mount is secure and properly aligned

- Wiring Considerations (for LED Whips):

- Route wiring along protected paths

- Leave service loops at connection points

- Use heat shrink or electrical tape on connections

- Secure wiring with zip ties every 6-8 inches

- Testing:

- Install and remove the whip several times to verify smooth operation

- Check that locking mechanisms engage properly

- For LED whips, test electrical connections

- Verify stability by gently pulling on the installed whip

Pro Installation Tips

Thread Locker Recommendations: Use medium-strength (blue) thread locker on mounting bolts, but avoid using it on quick-release components that need to move freely.

Grounding for LED Whips: Many LED whips require proper grounding. Some quick disconnect whip mounts include dedicated grounding wires to maintain electrical connection through the mount.

Weatherproofing Connections: For LED installations, use dielectric grease on electrical connections to prevent corrosion and ensure reliable operation.

Maintenance Schedule: Even the best quick disconnect systems benefit from occasional maintenance. Plan to clean and lubricate moving parts every 5-10 riding days, depending on conditions.

Maximizing Your Quick Disconnect Whip Mount

Once your quick disconnect whip mount is installed, consider these tips to get the most from your system:

Maintenance Best Practices

Cleaning Schedule: After rides in muddy, dusty, or salt-exposed environments, clean your mount thoroughly. Pay special attention to moving parts and locking mechanisms.

Lubrication Tips: Apply a small amount of silicone-based lubricant to moving parts every 3-5 rides. Avoid petroleum-based lubricants that can attract dust and debris.

Connection Inspection: Periodically check all mounting bolts and electrical connections for tightness and signs of corrosion.

Weather Protection: When possible, apply a light coat of protectant spray to metal components to prevent corrosion, particularly if you ride in coastal areas or during winter.

Troubleshooting Common Issues

Loose Connections: If your whip feels loose in the mount, check for wear on locking pins or receivers. Most quality mounts have adjustment points to compensate for wear over time.

Corrosion Prevention: White powdery residue on aluminum parts indicates corrosion. Clean thoroughly and apply appropriate protectants to prevent progression.

LED Connectivity Problems: Intermittent lighting usually indicates connection issues. Check ground wires and ensure any quick-disconnect electrical connectors are clean and making good contact.

Mounting Stability: If the entire mount seems loose, remove it completely, clean the mounting surface, apply fresh thread locker, and reinstall to proper torque specifications.

Accessories and Add-ons

Protective Covers: Some manufacturers offer weather covers for the mount when whips are removed, protecting threads and electrical connections.

Anti-theft Options: For additional security, consider security fasteners for the mount itself, protecting your investment even when whips are removed.

Multi-mount Adapters: These accessories allow mounting multiple whips to a single mount point – useful for running both a safety flag and LED whip simultaneously.

LED Wiring Upgrades: Consider quick-disconnect electrical connectors that separate when the whip is removed, simplifying the process and protecting connections.

Conclusion: Simple Solution, Significant Impact

Quick disconnect whip mounts represent a small investment with significant returns in convenience, protection, and flexibility.

While traditional mounting systems serve their basic purpose, the time savings and protection offered by quick disconnect options make them worth considering for any serious UTV enthusiast.

The ability to remove or install whips in seconds rather than minutes transforms what was once a tedious chore into a minor task.

This convenience encourages proper whip usage – you’re more likely to install safety whips when required if the process is simple and fast.

Similarly, you’re more likely to remove and protect expensive LED whips during transport if doing so doesn’t require a significant time investment.

When selecting a quick disconnect whip mount, consider your specific needs and riding style. Frequent transporters might prioritize folding designs that don’t require complete removal.

Those with expensive LED whips might focus on systems with integrated electrical connections. And riders who switch between vehicles might prefer universal options that can transfer between machines.

Whatever your specific requirements, the market now offers quick disconnect solutions to match.

Embrace the convenience these systems offer and enjoy more time riding and less time wrenching!