The quest for a truly sustainable off-road experience has long been a complex engineering puzzle.

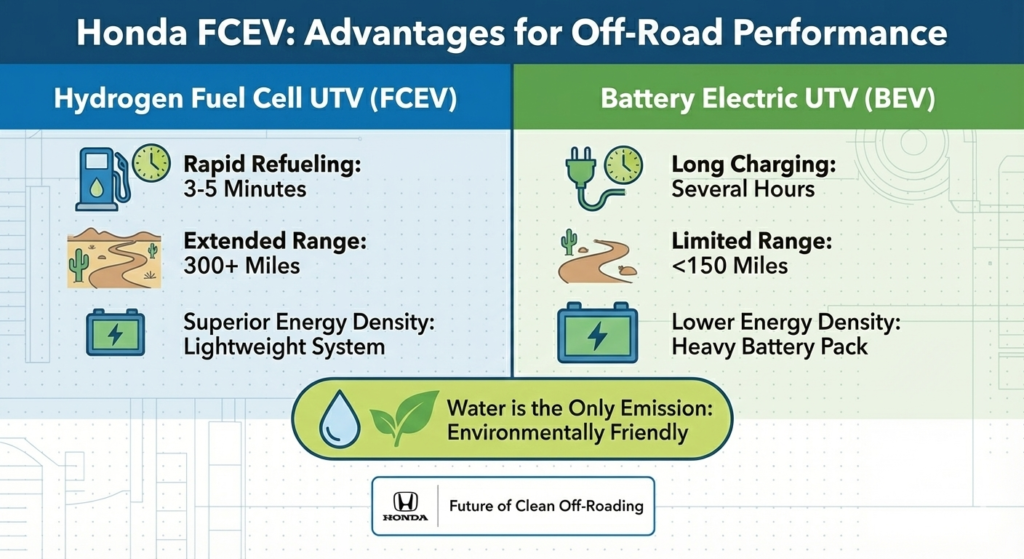

While battery-electric UTVs have made significant strides, they still grapple with the fundamental challenges of weight, charging time, and range anxiety in remote environments.

Enter the silent, powerful promise of hydrogen, a technology that Honda is aggressively pursuing as a cornerstone of its zero-emission future.

The concept of a hydrogen-powered Honda UTV is not a distant fantasy but a logical extension of the company’s advanced fuel cell research.

It represents a potential paradigm shift, offering the instant torque of electric power combined with the rapid refueling convenience of traditional gasoline engines, all with a zero-emission footprint.

Honda’s Fuel Cell Foundation: From Road to Trail

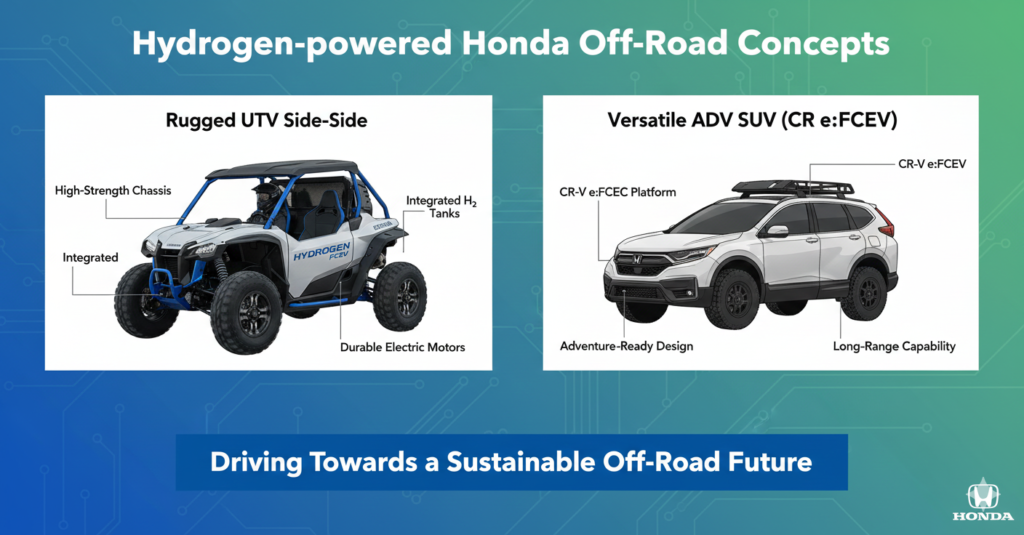

Honda is not new to the hydrogen game, having been a pioneer in Fuel Cell Electric Vehicles (FCEVs) for decades, and the latest iteration of this commitment is the CR-V e:FCEV, a vehicle that serves as the technological blueprint for future hydrogen applications, including the rugged world of UTVs [1].

This next-generation fuel cell system is smaller, lighter, and significantly more durable than its predecessors, making it an ideal candidate for the demanding conditions of off-road use where reliability is paramount.

The Next-Generation Fuel Cell Module: Efficiency and Durability

The core of Honda’s hydrogen strategy is its next-generation fuel cell module, developed in collaboration with General Motors, which boasts a production cost that is half that of the previous generation, a critical factor for making the technology commercially viable [2].

More importantly for UTV applications, it offers more than double the durability, which translates directly to reliability in harsh, vibrating off-road environments, a non-negotiable requirement for a side-by-side.

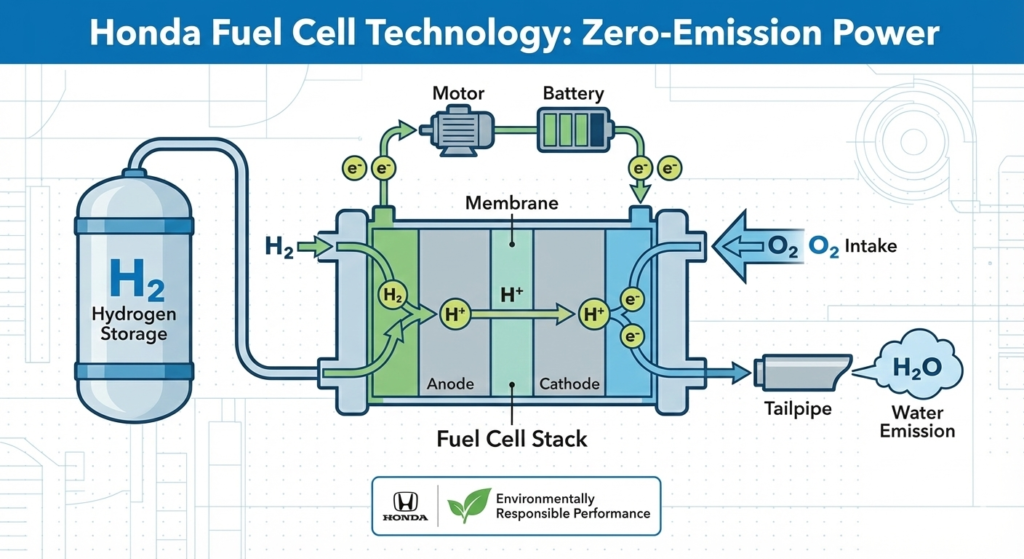

The system works by combining hydrogen gas from a high-pressure tank with oxygen from the air in a fuel cell stack, producing electricity to power the motors and water as the only emission, a process that is fundamentally cleaner than any combustion engine.

The reduction in platinum loading within the fuel cell stack is a key innovation, lowering the cost and the environmental impact associated with the mining of precious metals, a crucial step toward sustainable production.

Furthermore, the improved cold-start capability of the new module is vital for UTVs operating in diverse climates, ensuring reliable performance from the frozen mountain trails to the scorching desert floor.

The CR-V e:FCEV: A Dual-Power Blueprint

The CR-V e:FCEV is unique in that it is a plug-in FCEV, meaning it can be charged with electricity like a standard battery-electric vehicle, or refueled with hydrogen, offering a compelling dual-power capability [3].

This flexibility is particularly compelling for a UTV concept, as for short trips or work around a base camp, the battery could be charged via a standard outlet or a solar array.

For extended, multi-day expeditions into the backcountry, a quick hydrogen fill-up would restore maximum range in minutes, eliminating the hours-long wait associated with battery charging and solving the range anxiety problem.

The plug-in capability also allows the UTV to operate as a mobile power source, using its fuel cell to generate electricity for camp equipment, tools, or even emergency power, a feature that is highly valued in remote off-grid scenarios.

This bi-directional energy flow is a key differentiator from pure battery-electric UTVs, offering a level of versatility that is hard to match.

Conceptualizing the Hydrogen UTV: Design and Performance

Translating the fuel cell technology from a passenger car to a UTV requires a specialized design approach that addresses the unique demands of off-road performance, leveraging the primary advantages of hydrogen: low weight and high energy density.

Weight Distribution and Center of Gravity

Unlike large battery packs, which are heavy and must be placed low in the chassis, the hydrogen fuel cell stack and tanks can be more flexibly integrated into the UTV’s frame, often utilizing lightweight, incredibly strong carbon fiber composite tanks [4].

A conceptual Honda UTV could utilize a centralized, low-profile fuel cell stack with tanks strategically placed to optimize weight distribution, leading to superior handling and stability on uneven terrain.

This design would maintain the low center of gravity essential for high-speed cornering and climbing steep inclines, without the excessive mass of a large lithium-ion battery, a key performance advantage.

The modular nature of the fuel cell system also allows for a more balanced front-to-rear weight distribution, which is crucial for high-speed stability and predictable handling in dynamic off-road situations, where sudden shifts in weight can be detrimental.

Power Delivery and Torque Characteristics

Fuel cell systems power electric motors, which are inherently superior to combustion engines in terms of torque delivery, providing instantaneous maximum torque from zero RPM, a critical advantage for rock crawling, mudding, and steep hill climbs.

A hydrogen UTV would feature a sophisticated all-wheel-drive system, likely with independent electric motors at each wheel, allowing for precise torque vectoring and unparalleled traction control.

This level of electronic control would allow the UTV to navigate technical terrain with a finesse that mechanical systems simply cannot match, enhancing both safety and capability.

The ability to precisely control the torque at each wheel, known as e-axle technology, would virtually eliminate the need for traditional mechanical differentials, further simplifying the drivetrain and reducing the number of moving parts that can fail in harsh environments.

This precision also allows for advanced features like “tank turn” capability, where the UTV can pivot on its axis, a significant advantage in tight, technical terrain.

Thermal Management in Off-Road Conditions

A critical engineering challenge for fuel cell systems is thermal management, as the process of generating electricity produces heat that must be efficiently dissipated.

In a UTV, this challenge is compounded by the high ambient temperatures and the constant exposure to dust and debris.

Honda’s concepts would likely incorporate a robust, oversized cooling system, possibly utilizing a secondary fluid loop to manage the heat from the fuel cell stack and the electric motors, ensuring peak performance even under sustained high-load operation [9].

The design would need to ensure that the cooling intakes are strategically placed to minimize the ingestion of dust and mud, a common failure point in off-road vehicles.

The Infrastructure Hurdle and Honda’s Strategy

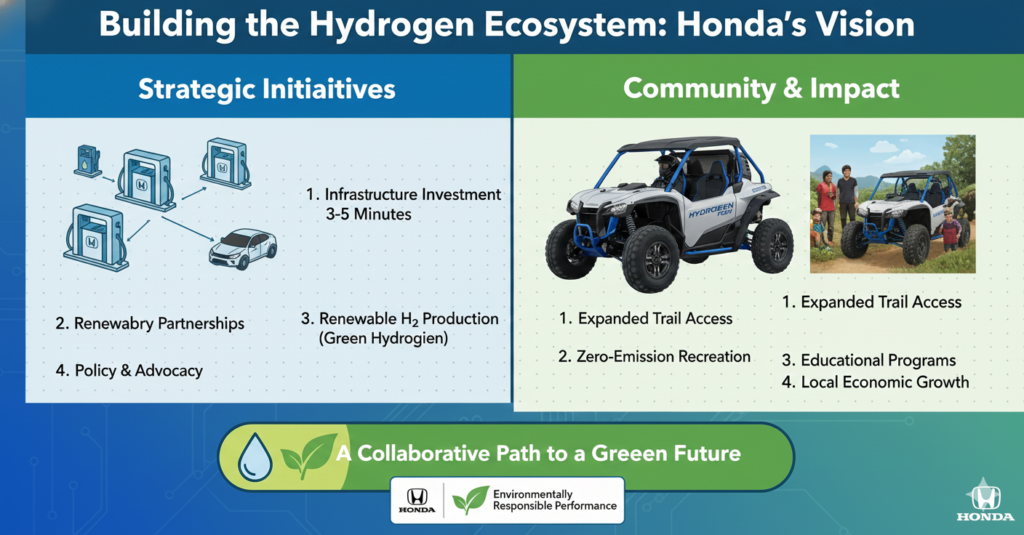

The most significant challenge for any hydrogen vehicle is the lack of a widespread refueling infrastructure, but Honda is actively working to address this through strategic partnerships and proof-of-concept projects that extend beyond passenger vehicles.

Industrial and Commercial Applications Driving Infrastructure

Honda’s hydrogen strategy includes a focus on commercial applications,

such as the proof-of-concept Class 8 hydrogen fuel cell truck in the U.S.,

which is crucial because it drives the development of regional hydrogen hubs and high-capacity refueling stations [5].

As these industrial networks grow, they will inevitably create opportunities for smaller-scale applications like UTVs,

particularly in areas near commercial ports, logistics centers,

or even remote mining and forestry operations that utilize heavy hydrogen equipment.

The development of high-pressure hydrogen storage and transfer protocols for these commercial applications will directly benefit the UTV market,

ensuring safe and efficient refueling procedures can be adapted for smaller, off-road stations.

Portable and Off-Grid Refueling Solutions

For the remote UTV market, the solution may lie in portable or localized hydrogen generation and storage,

bypassing the need for a massive, nationwide pipeline infrastructure.

Small-scale, modular hydrogen fueling stations could be deployed at major trailheads,

off-road parks, or remote resorts, utilizing renewable energy, such as solar or wind power, to perform electrolysis [6].

This decentralized approach would split water into hydrogen and oxygen, creating a truly closed-loop,

sustainable energy source for the UTV, making hydrogen viable for the off-road community much sooner.

The concept of a mobile hydrogen refueling trailer, capable of being towed to remote locations,

is a highly practical solution for organized UTV events or large-scale expeditions,

providing a temporary infrastructure where permanent stations are not feasible.

The Environmental and Economic Impact

The adoption of hydrogen UTVs would have profound environmental and economic benefits,

extending the promise of zero-emission recreation to the most demanding environments.

Zero Emissions, Zero Compromise

The primary environmental advantage is the complete elimination of tailpipe emissions,

including carbon dioxide, nitrogen oxides, and uncombusted hydrocarbons,

which is particularly important in sensitive ecosystems where air quality is paramount [7].

Furthermore, the fuel cell operates silently,

dramatically reducing the noise pollution that can disturb wildlife and detract from the natural experience for other trail users,

enhancing the overall quality of the wilderness experience.

When the hydrogen is produced using renewable energy—often referred to as “green hydrogen”—

the UTV’s operation is truly carbon-neutral, representing the pinnacle of sustainable off-roading.

A Sustainable Manufacturing Lifecycle and Recyclability

Honda’s commitment to sustainability extends to the entire lifecycle of the vehicle,

including the manufacturing process,

with fuel cell components designed for high durability and eventual recyclability [8].

The hydrogen UTV concept is a holistic approach to sustainability,

addressing not just the use phase but the entire chain of production and disposal,

aligning with the company’s broader goal of achieving carbon neutrality.

The materials used in the fuel cell stack, such as the membranes and catalysts,

are designed for high-efficiency recovery and recycling,

minimizing the need for virgin materials and closing the loop on the manufacturing process [10].

Economic Benefits for the Off-Road Community

While the initial cost of FCEVs can be higher,

the long-term economic benefits for the UTV community are significant.

Fuel cell systems require less maintenance than internal combustion engines,

as they have fewer moving parts, leading to lower operational costs over the vehicle’s lifespan.

Furthermore, the potential for using the UTV as a mobile power generator adds significant utility,

providing a return on investment that goes beyond simple transportation [11].

The hydrogen-powered Honda UTV remains a concept, but the underlying technology is real, proven, and rapidly advancing.

It represents a compelling future where off-road power and environmental responsibility are not mutually exclusive,

but perfectly integrated, promising a new era of silent, powerful, and clean exploration.

References

[1] Honda News. (2024, January 25). Next-Gen Honda Fuel Cell System Plays Key Role in Hydrogen Business Strategy. Retrieved from [URL for Honda News release]

[2] Honda Global. (2025, February 19). Honda Next Generation Fuel Cell Module. Retrieved from [URL for Honda Global news]

[3] Honda Automobiles. (n.d.). 2025 Honda CR-V e:FCEV | Hydrogen Fuel Cell Vehicle. Retrieved from [URL for Honda CR-V e:FCEV page]

[4] U.S. Department of Energy. (n.d.). Hydrogen Storage. Retrieved from [URL for DOE hydrogen storage resource]

[5] Honda News. (2024, January 25). Next-Gen Honda Fuel Cell System Plays Key Role in Hydrogen Business Strategy. Retrieved from [URL for Honda News release]

[6] National Renewable Energy Laboratory (NREL). (n.d.). Renewable Hydrogen Production. Retrieved from [URL for NREL hydrogen research]

[7] Environmental Protection Agency (EPA). (n.d.). Air Quality and Transportation. Retrieved from [URL for EPA air quality resource]

[8] Honda Global. (n.d.). Honda’s Environmental Initiatives. Retrieved from [URL for Honda sustainability page]

[9] Fuel Cell Thermal Management. (n.d.). Heat Dissipation in High-Performance Fuel Cells. Retrieved from [URL for Fuel Cell Thermal Management article]

[10] Fuel Cell Recycling Research. (n.d.). Material Recovery from End-of-Life Fuel Cells. Retrieved from [URL for Fuel Cell Recycling Research paper]

[11] Economic Analysis of FCEVs. (n.d.). Total Cost of Ownership for Hydrogen Vehicles. Retrieved from [URL for Economic Analysis of FCEVs report]