The internal combustion engine remains the heart of many UTVs, providing the raw power and range demanded by serious off-road enthusiasts.

However, the continued use of these engines is contingent upon their ability to meet increasingly stringent environmental regulations.

This has driven a wave of innovation in UTV emissions control technologies, transforming the modern side-by-side into a highly efficient, low-emission machine.

These technologies are complex, often unseen, but absolutely vital to the performance and legality of the vehicle, representing a triumph of engineering over environmental challenge.

Understanding them is key to appreciating the engineering marvel that allows high-performance engines to coexist with environmental stewardship.

The Three Pillars of Emissions Control

Emissions control in UTVs is focused on reducing three primary pollutants: uncombusted hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx), which are all byproducts of the combustion process.

The technologies used to achieve this can be grouped into three main categories: exhaust treatment, combustion optimization, and evaporative control, each addressing a different stage of the emission process [1].

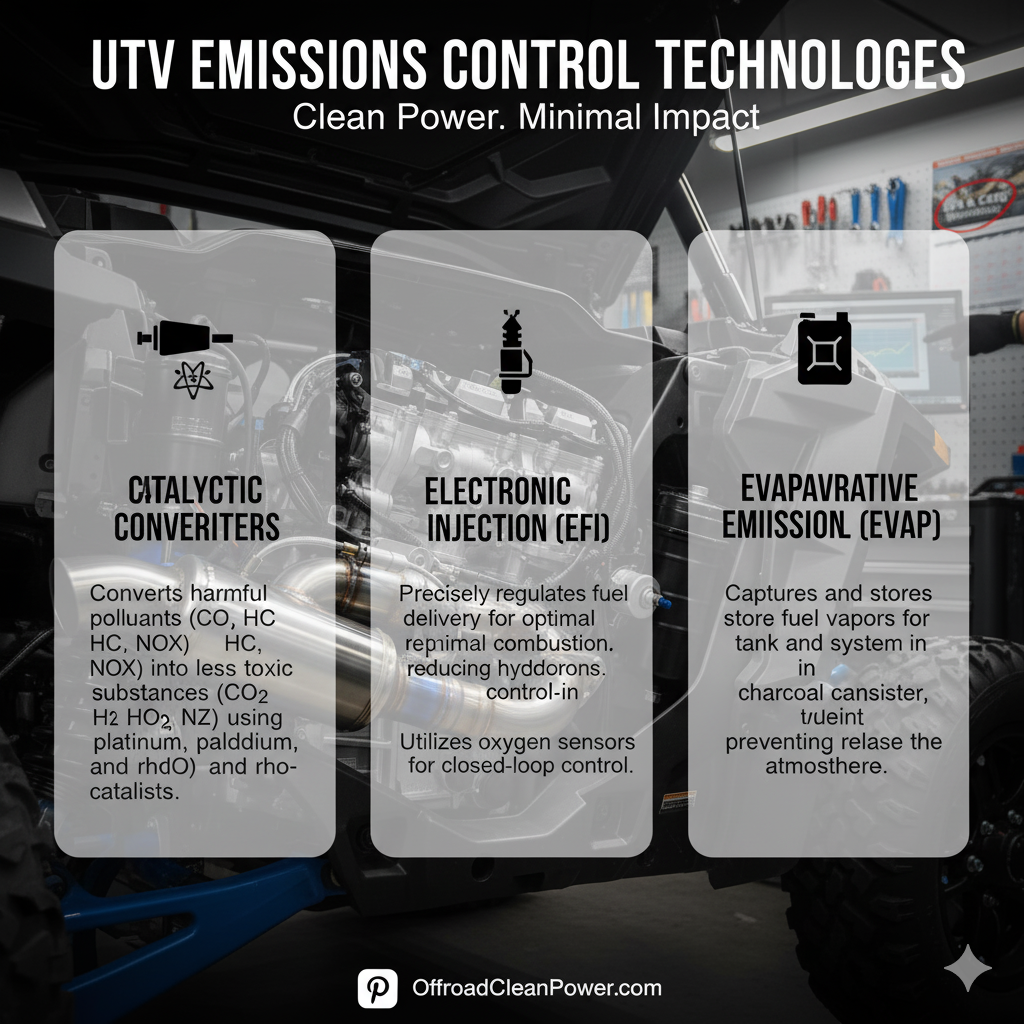

Exhaust Treatment: The Catalytic Converter

The most recognizable piece of emissions control equipment is the catalytic converter, a device placed in the exhaust stream that uses precious metals—typically platinum, palladium, and rhodium—as catalysts to convert harmful pollutants into less harmful substances.

It operates as a “three-way” catalyst, simultaneously performing three chemical reactions: the reduction of NOx to nitrogen and oxygen, the oxidation of CO to carbon dioxide (CO2), and the oxidation of uncombusted HC to CO2 and water vapor [2].

For the converter to function effectively, it must reach a high operating temperature, and the engine must maintain a precise air-fuel ratio, a task managed by the Electronic Control Unit (ECU).

The substrate of the converter, often a ceramic honeycomb structure, is designed to maximize the surface area for the chemical reactions, ensuring that the exhaust gases are thoroughly treated before exiting the tailpipe.

Combustion Optimization: Electronic Fuel Injection (EFI)

The shift from carburetors to Electronic Fuel Injection (EFI) has been a monumental step in emissions reduction, allowing for a level of precision previously unattainable.

EFI systems use sensors to monitor engine conditions—such as air temperature, engine speed, and throttle position—and precisely meter the amount of fuel injected into the combustion chamber.

The most critical sensor is the oxygen (O2) sensor, which measures the amount of oxygen in the exhaust gas, feeding this information back to the ECU in a “closed-loop” system [3].

This constant feedback loop allows the computer to constantly adjust the air-fuel ratio to the stoichiometric ideal—the perfect balance for complete combustion and optimal catalytic converter function.

Modern UTVs often employ wideband O2 sensors, which provide a more accurate and faster reading of the air-fuel ratio than traditional narrowband sensors, allowing for even more precise fuel metering and emissions control.

Evaporative Control: The EVAP System

Emissions do not only come from the tailpipe; a significant amount of uncombusted hydrocarbons can evaporate from the fuel tank and fuel lines, particularly on hot days.

The Evaporative Emissions Control (EVAP) system is designed to capture these fuel vapors before they escape into the atmosphere, routing them to a charcoal canister where they are temporarily stored [4].

When the engine is running under specific conditions, the ECU opens a purge valve, drawing the stored vapors into the engine to be burned, effectively eliminating a major source of pollution that is often overlooked.

The integrity of the EVAP system is crucial, and manufacturers use sophisticated pressure sensors and leak detection pumps to ensure that the entire fuel system remains sealed, preventing the escape of fugitive emissions.

Advanced Strategies for Compliance

To meet the latest standards set by bodies like the EPA and the California Air Resources Board (CARB), manufacturers are employing increasingly sophisticated secondary technologies that enhance the performance of the core systems.

Secondary Air Injection (SAI) and Cold-Start Mitigation

In some UTVs, a Secondary Air Injection (SAI) system is used to assist the catalytic converter, particularly during the cold-start phase when the converter is not yet hot enough to be fully effective.

This system pumps fresh air into the exhaust manifold, and the added oxygen helps to oxidize the uncombusted hydrocarbons and carbon monoxide in the exhaust stream, reducing their output until the main converter reaches its operating temperature [5].

This is a crucial strategy for reducing the “cold-start spike” in emissions, which is a major focus of modern regulations.

Another technique for cold-start mitigation is the use of close-coupled catalytic converters, which are placed immediately after the exhaust manifold to heat up faster, reaching their light-off temperature more quickly.

Engine Mapping for Off-Road Duty and Altitude Compensation

The ECU’s programming, or “mapping,” is tailored specifically for the unique demands of off-road driving, where the UTV operates under constantly changing loads, altitudes, and temperatures.

The ECU must be programmed to maintain the precise air-fuel ratio across this wide operating envelope, ensuring low emissions even during high-load climbing or low-speed technical maneuvers [6].

This advanced mapping is what allows a UTV to deliver maximum power while remaining compliant with environmental standards, a complex balancing act of performance and responsibility.

The ECU also incorporates altitude compensation, using barometric pressure sensors to adjust the air-fuel mixture to account for the thinner air at high elevations, which is critical for maintaining both performance and emissions compliance in mountain environments.

Exhaust Gas Recirculation (EGR)

While more common in diesel engines, some gasoline UTVs may utilize Exhaust Gas Recirculation (EGR) to reduce the formation of nitrogen oxides (NOx).

EGR works by routing a small portion of the exhaust gas back into the engine’s combustion chambers, which lowers the peak combustion temperature, thereby inhibiting the chemical reaction that creates NOx [11].

This technology is a key component in meeting the most stringent NOx reduction targets without sacrificing engine efficiency.

The Regulatory Landscape and Future Trends

The emissions standards for off-road vehicles are constantly evolving, pushing manufacturers to innovate and adopt cleaner technologies, ensuring a continuous reduction in the environmental impact of UTVs.

EPA and CARB Standards and Durability Requirements

The EPA sets federal emissions standards for all nonroad engines, including those in UTVs, under 40 CFR Part 1051, while CARB often sets even stricter standards, particularly for evaporative emissions [7].

These regulations dictate not only the maximum allowable levels of pollutants but also the durability requirements for the emissions control components, ensuring they function effectively for the vehicle’s full useful life, a critical factor for long-term environmental protection.

Manufacturers must demonstrate through rigorous testing that their emissions control systems will remain compliant for a specified number of operating hours or miles, a challenge that drives the use of more robust and reliable components.

The Role of Diagnostics (OBD) and Remote Monitoring

The next generation of UTVs is likely to incorporate more sophisticated On-Board Diagnostics (OBD) systems, similar to those found in passenger cars, which continuously monitor the performance of all emissions-related components [8].

These systems alert the driver to any malfunction that could lead to increased pollution, ensuring that emissions control systems are always operating at peak efficiency, which is a key component of long-term compliance and responsible ownership.

The future may also see the integration of remote emissions monitoring, where UTVs can wirelessly report their emissions status to regulatory bodies, ensuring real-time compliance and accountability across the entire fleet [12].

Maintenance and Operational Best Practices

The most advanced emissions control technology is only as good as its maintenance, and the UTV owner plays a critical role in ensuring these complex systems remain functional and effective.

Fuel Quality and Additives

The use of high-quality, clean fuel is essential for maintaining the integrity of the fuel system and reducing the risk of deposits that can foul oxygen sensors and catalytic converters [9].

Furthermore, avoiding the use of unauthorized fuel additives is crucial, as some can contain chemicals that damage the delicate catalyst materials, leading to premature failure of the emissions control system.

The use of ethanol-blended fuels, while common, requires careful consideration, as ethanol can be corrosive to certain fuel system components and can impact the long-term durability of the EVAP system.

Regular Sensor and Component Checks

The sensors—especially the O2 sensor—are the eyes and ears of the emissions control system, and regular checks and replacement according to the manufacturer’s schedule are essential for maintaining the closed-loop system’s accuracy [10].

A faulty O2 sensor can lead to an incorrect air-fuel ratio, resulting in increased emissions and poor engine performance, often without an immediate, obvious symptom, making proactive maintenance vital.

The Mass Air Flow (MAF) sensor is another critical component, as it measures the amount of air entering the engine, and a dirty or faulty MAF sensor can directly lead to an incorrect air-fuel mixture and increased emissions.

The Dangers of Tampering and Aftermarket Parts

Tampering with or removing emissions control equipment, such as the catalytic converter or the EVAP system, is illegal and severely compromises the UTV’s environmental performance.

While some aftermarket parts promise performance gains, they must be CARB-compliant or meet equivalent standards to ensure they do not increase the vehicle’s emissions beyond legal limits [13].

Responsible ownership dictates that all modifications must respect the integrity of the factory-installed emissions control systems, ensuring that performance and environmental responsibility go hand-in-hand.

The integration of sophisticated emissions control technologies has allowed the internal combustion UTV to remain a viable, high-performance option in an increasingly environmentally conscious world.

By respecting the complexity of these systems and adhering to best maintenance practices, riders can continue to enjoy the power of their machines while being responsible stewards of the environment.

References

[1] Environmental Protection Agency (EPA). (n.d.). Controlling Emissions from Nonroad Engines. Retrieved from [URL for EPA resource]

[2] Catalytic Converter Manufacturers Association. (n.d.). How Three-Way Catalytic Converters Work. Retrieved from [URL for CCMA resource]

[3] Bosch Automotive Technology. (n.d.). Electronic Fuel Injection Systems. Retrieved from [URL for Bosch technical paper]

[4] California Air Resources Board (CARB). (n.d.). Evaporative Emissions Control Systems. Retrieved from [URL for CARB EVAP resource]

[5] Society of Automotive Engineers (SAE). (n.d.). Secondary Air Injection for Emissions Reduction. Retrieved from [URL for SAE technical paper]

[6] Engine Control Unit Design. (n.d.). Off-Road Engine Mapping Strategies. Retrieved from [URL for ECU design article]

[7] U.S. Government Publishing Office. (n.d.). 40 CFR Part 1051 – Control of Emissions from Nonroad Spark-Ignition Engines. Retrieved from [URL for CFR 1051]

[8] OBD-II Standards. (n.d.). Future of On-Board Diagnostics in Nonroad Vehicles. Retrieved from [URL for OBD standards resource]

[9] Fuel Quality Institute. (n.d.). Impact of Fuel on Emissions Control Systems. Retrieved from [URL for Fuel Quality Institute article]

[10] Automotive Service Excellence (ASE). (n.d.). Oxygen Sensor Function and Diagnostics. Retrieved from [URL for ASE training material]

[11] Exhaust Gas Recirculation Technology. (n.d.). NOx Reduction in Small Engines. Retrieved from [URL for EGR Technology article]

[12] Remote Emissions Monitoring. (n.d.). Wireless Reporting for Nonroad Vehicles. Retrieved from [URL for Remote Monitoring resource]

[13] CARB Aftermarket Parts Compliance. (n.d.). Regulations for Emissions-Related Modifications. Retrieved from [URL for CARB Aftermarket resource]