great isn’t always enough. We crave that extra edge, that bespoke touch that truly makes our UTV an extension of ourselves and our adventurous spirit.

That’s where the magic of a custom tube chassis build for your Honda Pioneer comes into play.

For many, the idea of tearing down a perfectly good UTV to rebuild it from the ground up might seem daunting, even a little crazy.

But trust me, once you understand the profound benefits and transformative power of a custom tube chassis, you’ll start to see it not as a modification, but as an evolution.

It’s about taking an already capable machine and pushing its boundaries to levels you never thought possible, crafting a vehicle that’s perfectly tailored to your most extreme off-road desires.

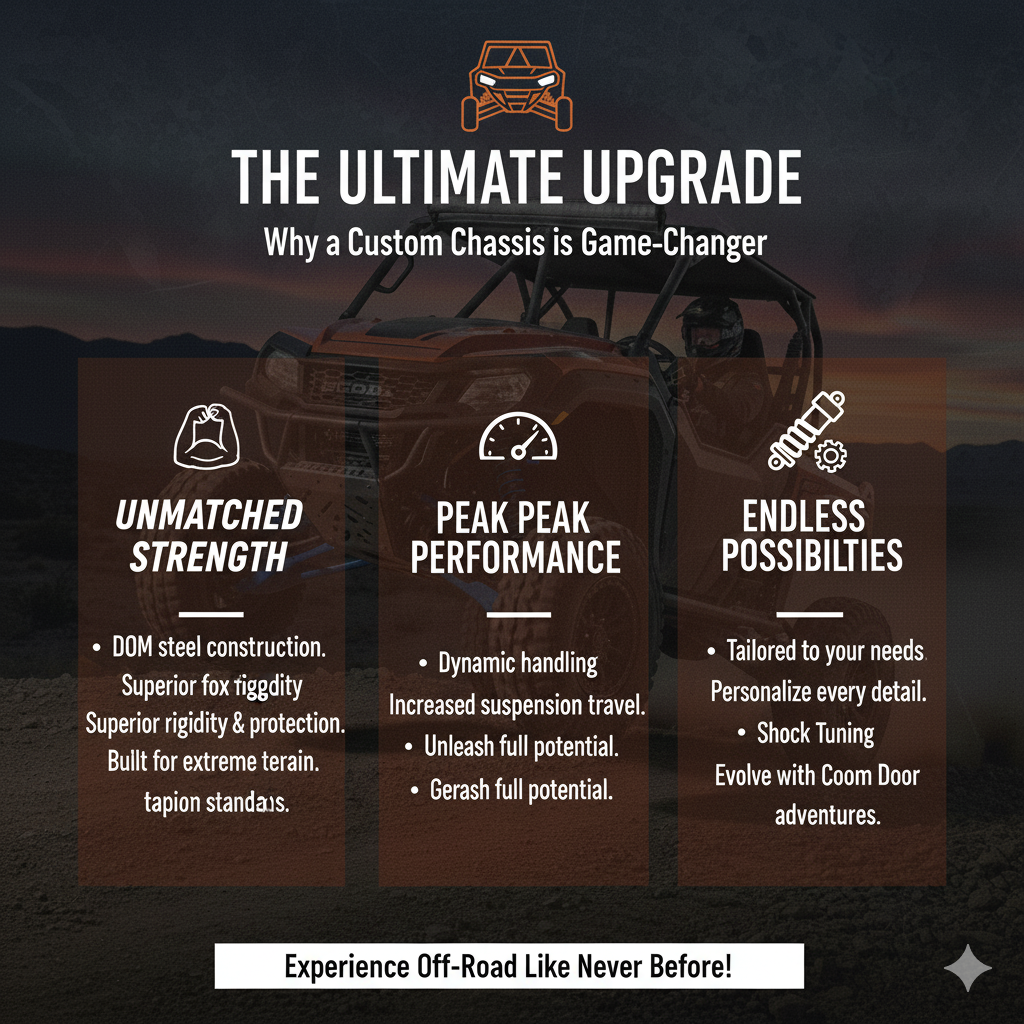

Why Go Custom? The Core Advantages of a Tube Chassis

So, what exactly makes a custom tube chassis such a game-changer for your Honda Pioneer?

It boils down to a few critical areas:strength, weight, performance, and customization.

Let’s break these down, because understanding these pillars is key to appreciating the engineering marvel that a well-built tube chassis represents.

1. Unrivaled Strength and Durability:

The stock frame of any UTV is designed for general use, balancing cost, manufacturing efficiency, and adequate strength for typical conditions.

However, when you start pushing your machine to its limits – tackling aggressive rock crawling, high-speed desert racing, or navigating treacherous terrains – those factory limitations can quickly become apparent.

A custom tube chassis, typically constructed from high-grade chromoly steel tubing, offers a significant leap in structural integrity. This isn’t just about surviving a rollover; it’s about providing a rigid, unyielding foundation that can withstand immense torsional forces and impacts without flexing or deforming.

This enhanced rigidity translates directly into a more predictable and safer ride, giving you the confidence to conquer obstacles you once shied away from.

2. Optimized Weight Distribution and Reduction:

One of the most compelling reasons for a custom chassis, especially in performance applications, is the ability to meticulously control weight.

A skilled fabricator can design a chassis that is not only stronger but also significantly lighter than the stock frame.

This weight reduction is crucial. Less weight means better acceleration, improved braking, and reduced stress on all other components.

More importantly, a tube chassis allows for precise weight distribution. Imagine being able to shift the center of gravity to optimize for hill climbing, rock crawling, or high-speed stability.

This level of fine-tuning is simply not achievable with a factory frame. For instance, some builders opt to move the engine forward in a tube chassis to achieve a better weight bias for specific challenges like hill climbing and rock crawling [1].

This strategic placement can dramatically improve traction and control in demanding situations.

3. Unleashed Performance Potential:

With increased strength and optimized weight comes a dramatic improvement in overall performance.

A more rigid chassis allows your suspension components to work more effectively.

When the frame flexes, it absorbs energy that should be managed by your shocks and springs.

A stiff tube chassis ensures that all suspension travel is dedicated to soaking up bumps and maintaining tire contact with the ground, leading to a smoother ride, better handling, and superior control.

This is particularly evident in the ability to run longer travel suspension systems, which can transform how your Pioneer handles rough terrain.

The UTVGuide.net article highlights a custom Honda Pioneer 1000 build that features a drool-worthy front J-arm/rear 4-link trailing arm design with fine-tuned Walker Evans Velocity Series 2.5” shocks, delivering a plusher ride than most stock UTVs [1].

This demonstrates the direct correlation between a robust chassis and high-performance suspension.

4. Limitless Customization and Integration:

Perhaps the most exciting aspect of a custom tube chassis is the freedom it provides for personalization.

When you’re not constrained by the factory layout, the possibilities are virtually endless.

Want to integrate a custom fuel cell? No problem.

Need specific mounting points for race-spec seats, advanced navigation systems, or specialized lighting?

A custom chassis allows for seamless integration of these components from the ground up. You can design the vehicle around your specific needs and preferences, creating a truly one-of-a-kind machine.

This includes everything from the placement of the engine and drivetrain components to the design of the bodywork and interior.

The UTVGuide.net build, for example, retained the Honda Pioneer 1000’s engine, electronics, front and rear diffs, radiator, brakes, and CVs, but built custom longer axles, knuckles, suspension arms, and a custom aluminum body [1].

This showcases how a custom chassis allows for the retention of desirable factory components while completely reimagining the vehicle’s structure and capabilities.

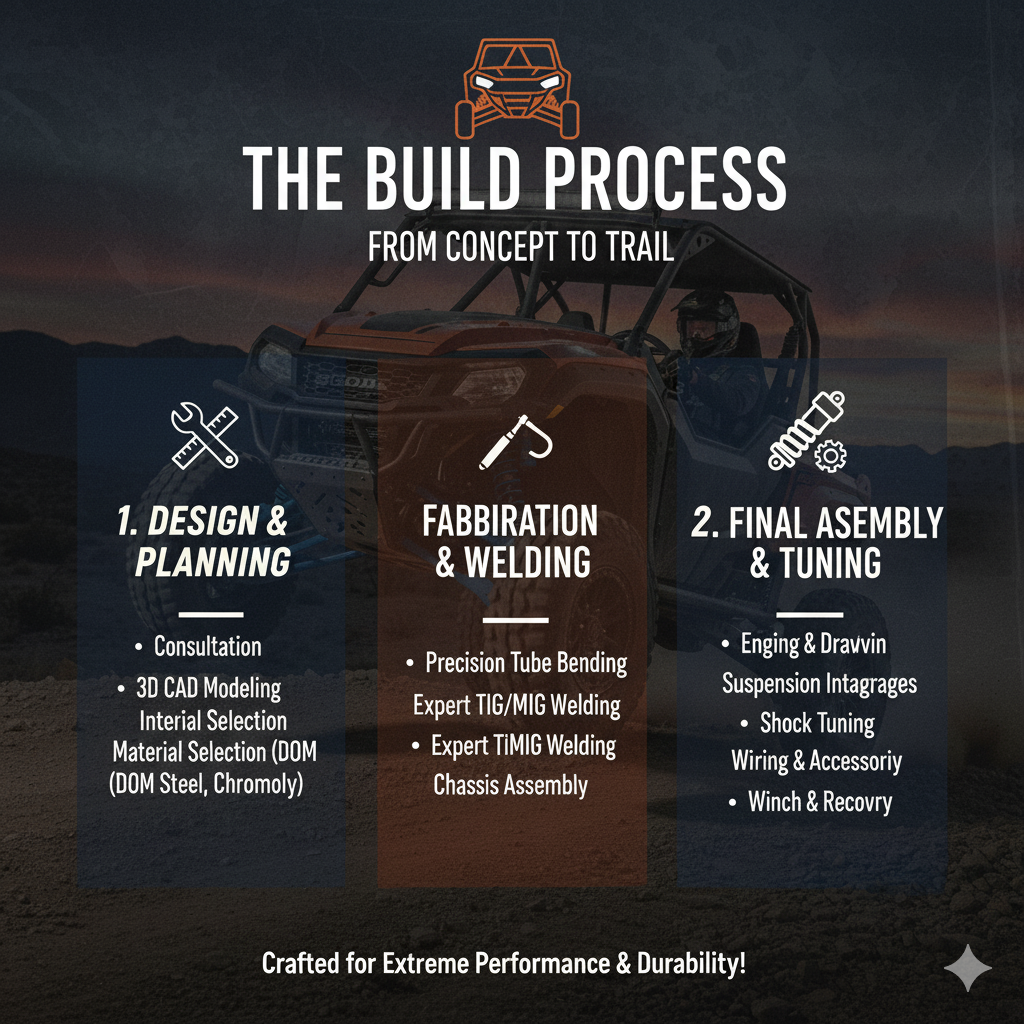

The Build Process: From Concept to Conqueror

Embarking on a custom tube chassis build is a significant undertaking, but the journey itself is often as rewarding as the final product.

It typically involves several key stages, each requiring meticulous planning, skilled craftsmanship, and a deep understanding of off-road dynamics.

1. Design and Engineering:

This is where the vision takes shape. Working with experienced fabricators and engineers is crucial at this stage.

They’ll consider your intended use – whether it’s desert racing, rock crawling, or extreme trail riding – and design a chassis that meets your performance goals and safety requirements.

This often involves CAD software to create precise blueprints, ensuring optimal geometry, suspension mounting points, and component placement.

The goal is to achieve maximum strength with minimal weight, while also allowing for easy maintenance and access to critical components.

Russ Wernimont, credited as the original innovator behind modern Trophy Trucks, was instrumental in the chassis design and build of the custom Honda Pioneer 1000 featured on UTVGuide.net, highlighting the importance of expert design [1].

2. Fabrication and Welding:

Once the design is finalized, the actual fabrication begins. High-quality chromoly tubing is carefully cut, bent, and TIG welded to form the chassis.

This is an art form, requiring precision and expertise to ensure every joint is strong and perfectly aligned.

The quality of the welds is paramount, as they are critical to the structural integrity of the entire vehicle. A well-fabricated chassis will be a work of art in itself, showcasing the craftsmanship that goes into its construction.

3. Component Integration:

With the chassis complete, the process shifts to integrating all the necessary components.

This includes mounting the engine, transmission, differentials, and other drivetrain elements.

The suspension system is installed, often featuring long-travel shocks and custom control arms designed to work seamlessly with the new chassis geometry.

Fuel cells, cooling systems, and electrical wiring are also carefully routed and secured.

This stage demands careful planning to ensure everything fits perfectly and functions harmoniously.

The custom Pioneer build, for instance, utilized the stock Honda Pioneer 1000 engine and transmission, integrating them into the new chassis along with custom exhaust and intake systems [1].

4. Bodywork and Finishing:

Finally, the custom bodywork is designed and fitted.

This can range from minimalist panels to elaborate, aerodynamic designs, all crafted to complement the new chassis and provide protection for the occupants and components.

Painting, powder coating, and graphics are then applied, giving the UTV its unique aesthetic.

The UTVGuide.net article mentions King Adam the Great building a custom aluminum body for the Honda Pioneer, demonstrating the level of bespoke artistry involved in this stage [1].

The interior is also customized, often with race-spec seats, harnesses, and a custom dash to house navigation and communication equipment.

The custom dash in the UTVGuide.net build, for example, integrated the stock gauge cluster, a Lowrance HDS 5m GPS, a Mob Armor iPad mount, and Rugged Radios communication equipment [1].

The Honda Pioneer: A Perfect Candidate for Transformation

The Honda Pioneer 1000, with its robust 999cc engine and dual-clutch transmission, provides an excellent foundation for a custom tube chassis build. Its engine package is known for being incredibly smooth, quiet, and reliable, offering a refined ride not often found in the UTV segment [1].

The six-speed dual-clutch transmission gives complete driver control without the worry of clutch modulation, making it ideal for navigating challenging terrains [1].

Furthermore, retaining the stock driveline means benefiting from Honda’s four differential modes – turf mode, 2WD, 4WD, and 4WD with front differential lock – offering unparalleled versatility [1].

These attributes make the Pioneer an ideal donor vehicle, allowing builders to leverage its proven powertrain while completely upgrading its structural and suspension capabilities.

Is a Custom Tube Chassis Right for You?

Deciding whether a custom tube chassis build is the right path for your Honda Pioneer depends on your aspirations and budget.

It’s an investment, both in terms of time and money, but the payoff for serious off-road enthusiasts can be immense.

If you’re someone who constantly seeks to push the limits of your machine, demands the highest levels of performance and safety, and desires a UTV that is truly unique and tailored to your exact specifications, then a custom tube chassis is undoubtedly worth considering.

It’s about more than just owning a UTV; it’s about owning a piece of engineering art, a machine built with passion and precision to conquer any trail, dune, or rock garden you dare to challenge.

So, if you’re ready to transform your Honda Pioneer into an absolute beast, start exploring the possibilities of a custom tube chassis build. The off-road world awaits your ultimate creation!

References

[1] Nordin, R., & Hooper, C. (2017, April 11). *Full-Tilt Custom Chassis UTV Using Honda Pioneer 1000 Drivetrain*. UTV Guide. Retrieved from