A.1. The Economics of Predictive Maintenance (PdM) in Off-Roading

Predictive Maintenance (PdM) represents a paradigm shift in equipment management, moving operators from reacting to failures to anticipating them.

PdM utilizes sophisticated data and analytics to predict exactly when a vehicle or component is likely to fail, enabling maintenance intervention weeks before a breakdown actually occurs.

This data-driven approach is significantly more efficient than time-based maintenance (TBM), which follows fixed schedules regardless of actual equipment condition, often resulting in unnecessary maintenance and resource waste.

The financial motivation for implementing PdM in high-value assets like UTVs is compelling.

Industry data suggests that PdM programs can yield a potential return on investment (ROI) of approximately ten times the initial cost.

This exceptional ROI is achieved primarily by minimizing costly unplanned downtime and eliminating the need for rush orders for parts and emergency towing services.

For off-road enthusiasts who subject their machines to extreme stress, this translates directly to increased uptime and reliability.

PdM fundamentally relies on condition monitoring (CBM) techniques to gather the necessary data.

The key modalities for detecting mechanical degradation include:

- Vibration Analysis: Using sensors like accelerometers mounted directly on machinery to detect anomalies indicating mechanical imbalance, misalignment, or looseness.

- Infrared Thermography: Using thermal cameras or sensors to monitor asset condition based on heat transfer, identifying areas of excessive friction or thermal load.

- Fluid Analysis: Analyzing oil and fluid samples to detect chemical degradation or the presence of microscopic wear metals.

A.2. First-Order Data Integration: The Value of Planning

One of the most immediate benefits of adopting a PdM strategy is the ability to integrate failure alerts with maintenance scheduling.

Telematics—the integrated use of telecommunications and informatics to send, receive, and store vehicle data—is the backbone of this capability.

Telematics systems in heavy equipment already track key data such as location, speed, engine hours, and diagnostic trouble codes (DTCs).

When a predictive fleet maintenance solution identifies a pattern likely to lead to a distinct failure, it generates an alert in real-time.

This early warning allows riders or fleet managers to schedule necessary repairs during planned vehicle downtime, completely avoiding trailside catastrophes and expensive emergency recovery operations.

This capability transforms maintenance into a proactive, predictable cost center rather than a reactive crisis.

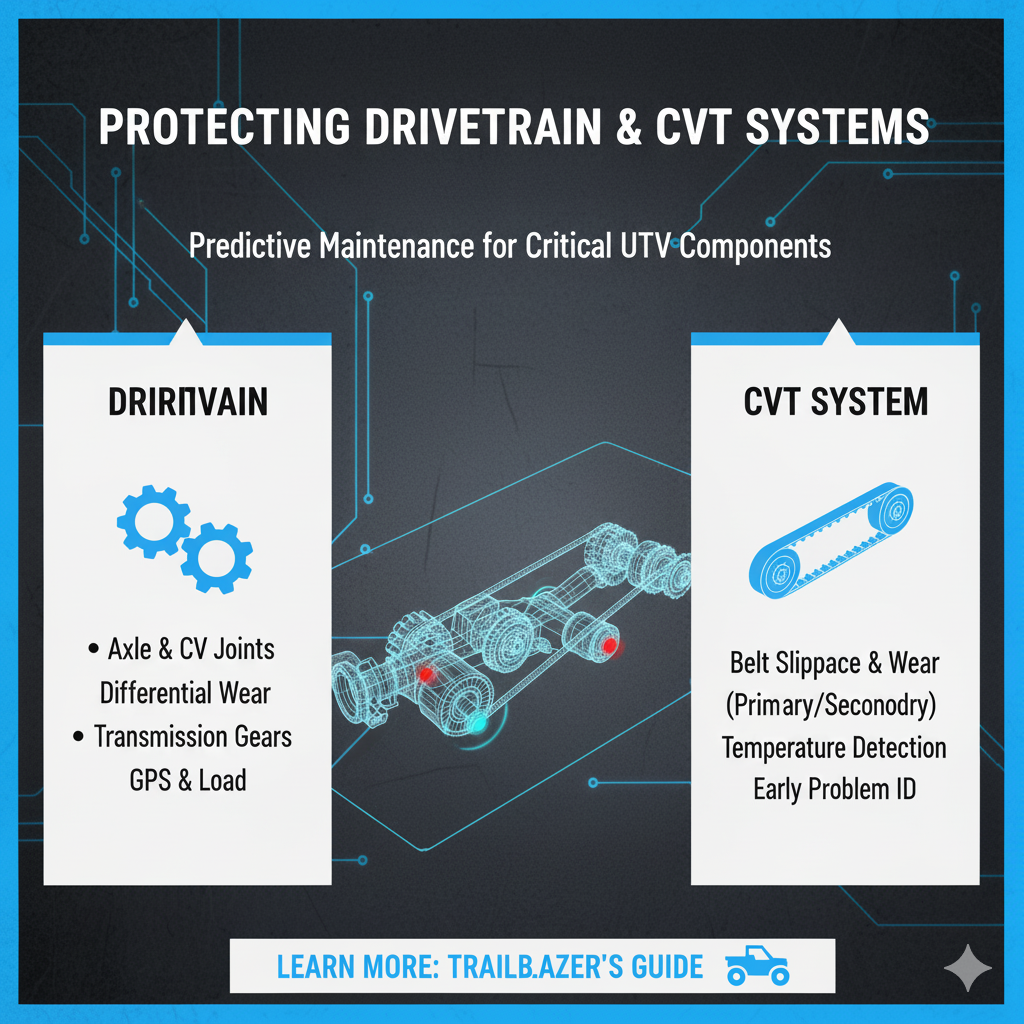

B. PdM Focus Area 1: Managing CVT Thermal Load and Belt Degradation

The Continuously Variable Transmission (CVT) system, common in high-horsepower UTVs, is essential for translating engine torque to the wheels but is highly sensitive to thermal stress.

Effective PdM here centers almost entirely on monitoring and mitigating heat.

B.1. The Critical Thermal Threshold

The CVT belt is particularly susceptible to thermal degradation, which leads to overheating, stretching, and premature catastrophic failure.

This process accelerates when continuous operation pushes the belt past its safe working limits.

Technical analysis indicates that the critical failure point for the CVT belt is reached when sustained surface temperatures exceed 200 °F.

To monitor this critical parameter in real-time, infrared (IR) technology is essential as it measures the belt surface temperature non-intrusively.

Aftermarket manufacturers provide commercial systems, such as infrared belt temperature gauges for Polaris RZR models, featuring bright, anti-glare LCD screens that display current, average, and high temperatures.

These systems incorporate multicolor LED temperature alerts that instantly notify the operator when temperatures rise into caution or danger zones, proactively signaling the need to reduce load or stop to cool down.

This constant monitoring extends belt longevity and prevents major failures.

B.2. Tuning, Load, and Heat Correlation

Understanding the factors that contribute to heat buildup is crucial for maximizing performance without exceeding the 200°F threshold.

CVT performance relies on precise clutch calibration—adjusting primary clutch weights and secondary spring/helix settings—to keep the engine RPM consistently within the optimal power band (typically 7700–8000 RPM at Wide Open Throttle).

When the clutch is tuned, adjustments follow fundamental rules: adding weight to the primary clutch lowers the RPM, while removing weight raises the RPM.

External factors impose significant strain on the system, directly correlating with heat generation.

For example, operating at high altitudes requires subtracting approximately 15% from the tuning target due to reduced air density and lower available horsepower.

Similarly, running oversized tires or driving in heavy sand or mud requires subtracting roughly 8% from the tuning target to compensate for increased rolling mass and resistance.

Failure to compensate for these environmental or modification-induced loads results in belt slippage and excessive heat, pushing the system toward the critical failure point.

Furthermore, maintenance habits, such as ensuring clutch vents are clean and unobstructed, are vital, as restricted airflow leads to belt overheating.

Installing ventilation scoops can enhance cooling by utilizing ram air to break up stale, hot air in the belt housing.

B.3. Data-Driven Optimization

The application of real-time CVT temperature monitoring fundamentally changes the process of clutch tuning.

Historically, riders relied on qualitative indicators like the smell of burning rubber or catastrophic belt failure to judge tuning correctness.

By adopting PdM technology, the performance adjustment process moves from anecdotal guesswork to verifiable data analysis.

For instance, if a UTV performs a WOT pull in dune sand, and the infrared gauge instantly reads above 200°F, the driver immediately has objective, quantitative evidence that the current clutch calibration is incorrect for the load and terrain, indicating excessive belt slip and heat generation.

This capability transforms tuning from an inexact “art” into a measurable, iterative “science”.

The data provided by the IR sensor validates whether adjustments—such as moving weight from the tip to the heel of the clutch arms to stabilize RPM—successfully lowered the thermal load while maximizing power transfer and response.

C. PdM Focus Area 2: Drivetrain Component Degradation

The drivetrain components—specifically axles, CV joints, and wheel hub assemblies—are major sources of mechanical failure in UTVs, especially when subjected to large tires, lift kits, and high torque.

C.1. Axle and CV Joint Failure Prevention

Stock CV axles are often considered the weakest link in a modified UTV’s drivetrain, leading to failure when stressed by increased power and larger wheels.

The primary failure mechanisms for CV joints include axle binding, where the articulation angle exceeds the joint’s design limit, causing internal locking and catastrophic failure of the cage and bearings.

This is compounded by high heat caused by aggressive suspension angles, which degrades the lubricating grease into a thinner consistency, rapidly reducing the CV joint’s lifespan.

To counter this, many enthusiasts upgrade to high-end aftermarket axles, such as SuperATV Rhino 2.0 or Gorilla Axles.

These are typically constructed from heat-treated 4340 Chromoly steel—a robust nickel-chromium-molybdenum alloy—and engineered to handle severe CV angles exceeding 40 degrees, often rated at least twice as strong as OEM units.

Predictive maintenance in this area extends beyond simply buying stronger parts; it involves continuously monitoring the health of these components using fluid analysis.

By routinely collecting oil samples from the differential and transmission and submitting them to commercial labs like Blackstone or Oil Analyzers (AMSOIL), trace amounts of wear metals (such as Iron, Copper, and Lead) can be detected.

This elemental analysis provides a forecast of internal component degradation (differential gears, bearings, or sprague cages) weeks before physical symptoms like grinding noises or fluid leaks appear.

C.2. Preventing Catastrophic Wheel Hub Failure

Wheel bearings are consumables that inevitably fail due to contamination and load, producing symptoms like excessive play or grinding noises.

The real cost of wheel bearing failure is not the price of a replacement bearing itself (which can range from $50 to $250 for aftermarket options).

The major financial risk is the collateral damage caused by persistent operation on a failed bearing: friction and heat can destroy the surrounding, high-cost components, specifically the steering knuckle or spindle.

Replacing a damaged steering knuckle involves complex labor and costly components.

Part prices alone for knuckles and associated steering components can range from $350 to well over $1,000 per side.

Applying CBM through vibration analysis (using accelerometers) or even simple, low-cost infrared spot checks of the hub temperature can predict bearing decay early enough to schedule a simple, inexpensive bearing replacement.

This minimal diagnostic investment protects the high-cost knuckle assembly, providing a demonstrable ROI by preempting secondary, catastrophic mechanical failures.

C.3. Differential Reinforcement and Lockers

For vehicles engaging in extreme torque applications, differential strengthening is often necessary.

Performance differentials often feature robust construction, such as upgraded differential housings made from billet aluminum, which provide improved strength and rigidity, often aiding in heat dissipation compared to factory cast aluminum cases.

Furthermore, these housings frequently incorporate steel helical inserts for the mounting threads, which are proven to prevent the threads from wallowing out or coming loose under extreme impact and vibration.

A key decision for extreme off-roaders is the choice between a spool and a selectable locker.

A full spool physically locks both axles together 100% of the time, transmitting equal torque to both wheels for maximum straight-line acceleration and traction, making it ideal for drag racing or dedicated competition rigs.

However, this locking action forces the wheels to fight when turning, resulting in poor cornering stability.

In contrast, a selectable locking differential offers flexibility: it allows the wheels to turn independently during normal operation, preserving handling, but can be manually locked when maximum traction is required in loose terrain or rock crawling.

C.4. Protecting High-Value Modifications

Owners who invest in high-performance drivetrain upgrades often mistakenly believe these components are invulnerable.

High-strength materials like Chromoly steel used in premium axles are substantially stronger than OEM counterparts.

However, even Chromoly axles remain susceptible to environmental ingress.

A torn CV boot is the primary killer of CV axles, allowing dirt and debris to enter the constant velocity joint, leading to accelerated wear and eventual failure.

Since upgraded axles represent a significant investment (often over $235 per axle) , maintaining these components is paramount.

Routine inspection combined with continuous condition monitoring, such as using infrared thermography to confirm that the CV boots and joints are operating below temperatures that degrade the synthetic grease, acts as an essential safeguard.

This application of PdM safeguards the designed longevity and preserves the inherent reliability of expensive aftermarket components.

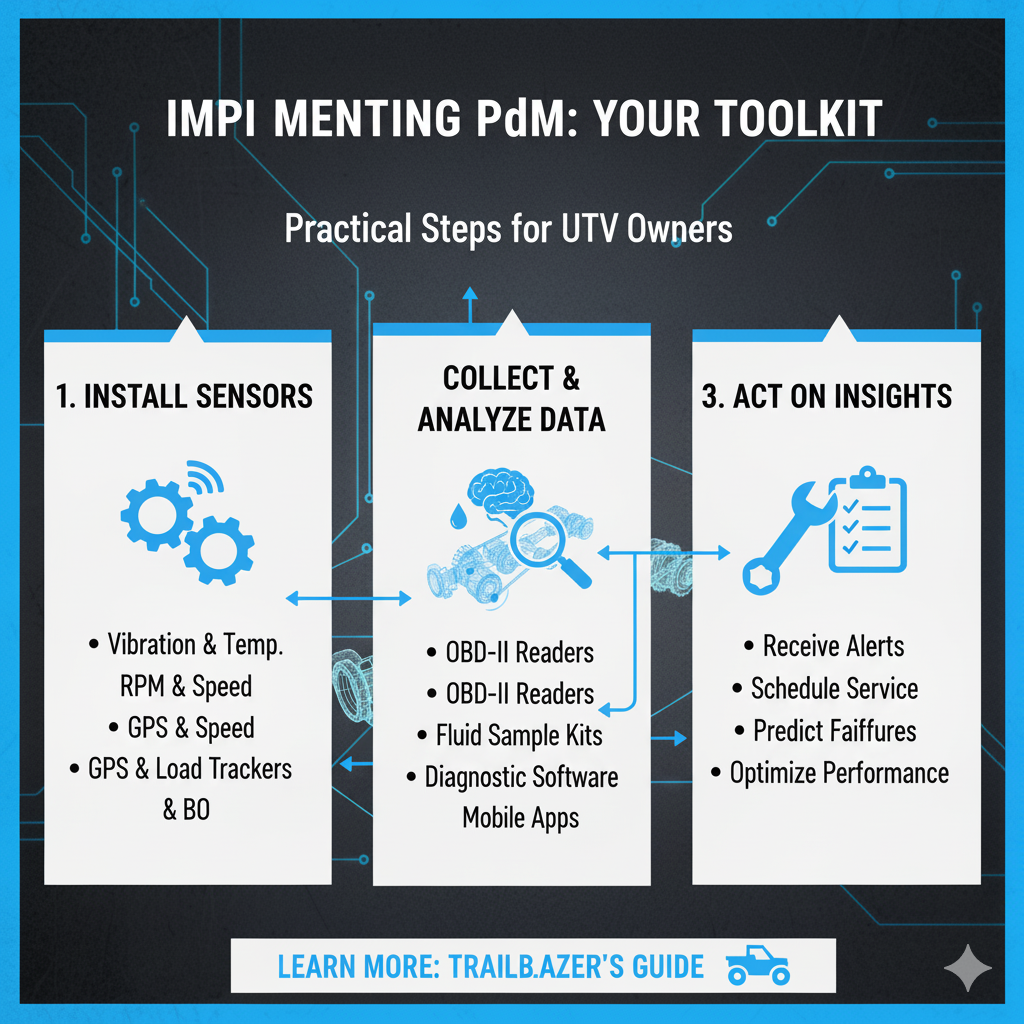

D. The DIY PdM Data Center: Tools, Telematics, and Diagnostics

For the individual UTV owner, implementing a practical PdM program requires selecting effective and accessible diagnostic and monitoring equipment.

D.1. ECU Access and Telematics

While professional diagnostic tools used by manufacturers (such as Polaris’s Digital Wrench or BRP’s BUDS system) offer deep access to the Engine Control Unit (ECU), they are proprietary, licensing-dependent, and generally cost-prohibitive for private owners.

A more practical pathway for the serious enthusiast is adopting aftermarket diagnostic tools.

Modern consumer-level scanners, such as the TOPDON ArtiDiag Moto or OTB Check Tech, provide comprehensive system coverage, allow the reading of Diagnostic Trouble Codes (DTCs), and monitor live data feeds for major brands like Polaris, Can-Am, and Honda.

These tools enable the operator to establish a critical performance baseline for the engine and track deviations over time.

Similar to heavy industrial equipment, the telematics data points collected often include fault codes, current engine hours, and vehicle health status.

This data feeds the predictive models utilized by the owner, often manifesting as simple trending charts or user-defined threshold alarms.

D.2. Practical Condition Monitoring Tools for DIY

Effective PdM requires actionable data gathered outside the ECU interface:

- Infrared (IR) Thermometer: A low-cost handheld IR thermometer is crucial for non-contact temperature spot checks on the CVT clutch case, wheel bearings, and differential housings. This readily available tool allows the user to quickly verify thermal load and detect hot spots indicative of premature wear.

- Fluid Analysis Kits: Kits from providers like Blackstone Labs or Oil Analyzers (AMSOIL) are indispensable. For $30 to $70 per kit, an owner can submit samples of engine, transmission, or differential fluid. The resultant Elemental Analysis report provides a quantitative breakdown of wear metals, flagging potential issues like bearing or piston ring failure before external symptoms appear. This is an essential component of deep predictive monitoring for internal moving parts.

D.3. Implementing the DIY PdM Roadmap

Implementing a personal PdM system involves a strategic, phased approach, starting with asset prioritization.

The core steps include:

- Asset Prioritization: Identify assets whose failure results in the highest downtime and repair cost (typically the engine, CVT, and wheel hubs). Track usage using an hour meter, as many UTV maintenance schedules are based on operating hours.

- Data Baseline: Collect baseline data by performing an initial fluid analysis and comprehensive diagnostic scan with an aftermarket tool.

- Sensor Deployment: Deploy key CBM tools, such as installing a permanent IR sensor for continuous belt monitoring.

- Threshold Establishment: Define clear “Red Zone” maintenance triggers, such as an alarm for a CVT belt temperature exceeding 200°F , or a fluid analysis report indicating high Iron (Fe) content pointing toward excessive gear wear.

D.4. The Value of Multimodal Data Validation

In dynamic, high-stress off-road environments, wear and tear is highly volatile.

Simply relying on the intermittent DTC codes provided by a relatively inexpensive aftermarket scanner is insufficient for true predictive analysis.

Advanced predictive models rely on high-volume, high-quality data integrated across multiple sources.

For the UTV enthusiast, this necessity translates to layering multiple CBM techniques.

The fluid analysis report acts as the critical independent verification of mechanical health (the “ground truth”) for internal components.

If the diagnostic scanner records intermittent ECU fault codes, and the fluid analysis shows a corresponding spike in wear metals, the owner has reliable, multimodal data confirming an impending failure weeks away.

This layered monitoring system is necessary to accurately forecast equipment health and ensures that preventive actions are taken based on robust data, maximizing the return on the CBM technology investment.

E. Conclusion: Uptime is the Ultimate Upgrade

Predictive maintenance technology, once limited to complex industrial machinery, is now accessible and vital for maximizing the performance and longevity of high-performance UTVs.

By systematically integrating real-time sensor monitoring (CVT belt temperature), periodic fluid analysis (engine and differential health), and affordable diagnostic tools (ECU error reporting), the modern enthusiast can transition from costly reactive repairs to cost-effective, planned maintenance.

This proactive strategy protects the vehicle’s most vulnerable and expensive components, ensuring maximum power delivery and, most importantly, achieving maximum ride time.