The Cosmic Pioneer: How Honda’s UTV Tech is Ready for Space

Hello, space cadets and off-road explorers!

We spend a lot of time conquering Earth’s toughest terrain with our Honda Pioneers.

But what if I told you that the very DNA of your UTV—its reliability, its robust mechanical systems, and its focus on utility—is perfectly suited for the ultimate off-road challenge: space exploration?

As NASA and private companies like SpaceX gear up for a sustained human presence on the Moon and Mars, the need for reliable, versatile, and tough surface vehicles is paramount.

These rovers need to be more than just science labs; they need to be utility vehicles, capable of hauling cargo, supporting construction, and performing long-distance reconnaissance.

In short, they need to be the Honda Pioneer of the Cosmos.

Let’s break down how the core technologies of the Pioneer could be adapted for the harsh, unforgiving environments of the Moon and Mars.

1. The Power of the Dual Clutch Transmission (DCT)

The biggest hurdle for any mechanical system in space is the vacuum, extreme temperatures, and fine, abrasive dust (regolith).

The Pioneer’s DCT transmission, a mechanical marvel, offers a massive advantage over traditional systems.

- Precise Power Delivery: The DCT provides precise, mechanical engagement of gears, which is crucial for low-speed maneuvering and climbing steep craters. In a low-gravity environment, the instantaneous, controlled torque of the DCT would prevent wheel spin and ensure maximum traction.

- Sealed System: Unlike a CVT (which relies on a constantly moving, exposed belt), the DCT is a fully sealed, oil-bath system. This is a huge benefit in a dusty environment like Mars. The fine regolith is highly abrasive and would quickly destroy an exposed belt. The sealed DCT protects the gears and clutches, ensuring long-term reliability.

- Engine Braking: The Pioneer’s legendary engine braking (even if the “engine” is an electric motor in space) is a critical safety feature. On a steep lunar slope, the ability to mechanically slow the vehicle without relying solely on friction brakes is a life-saver.

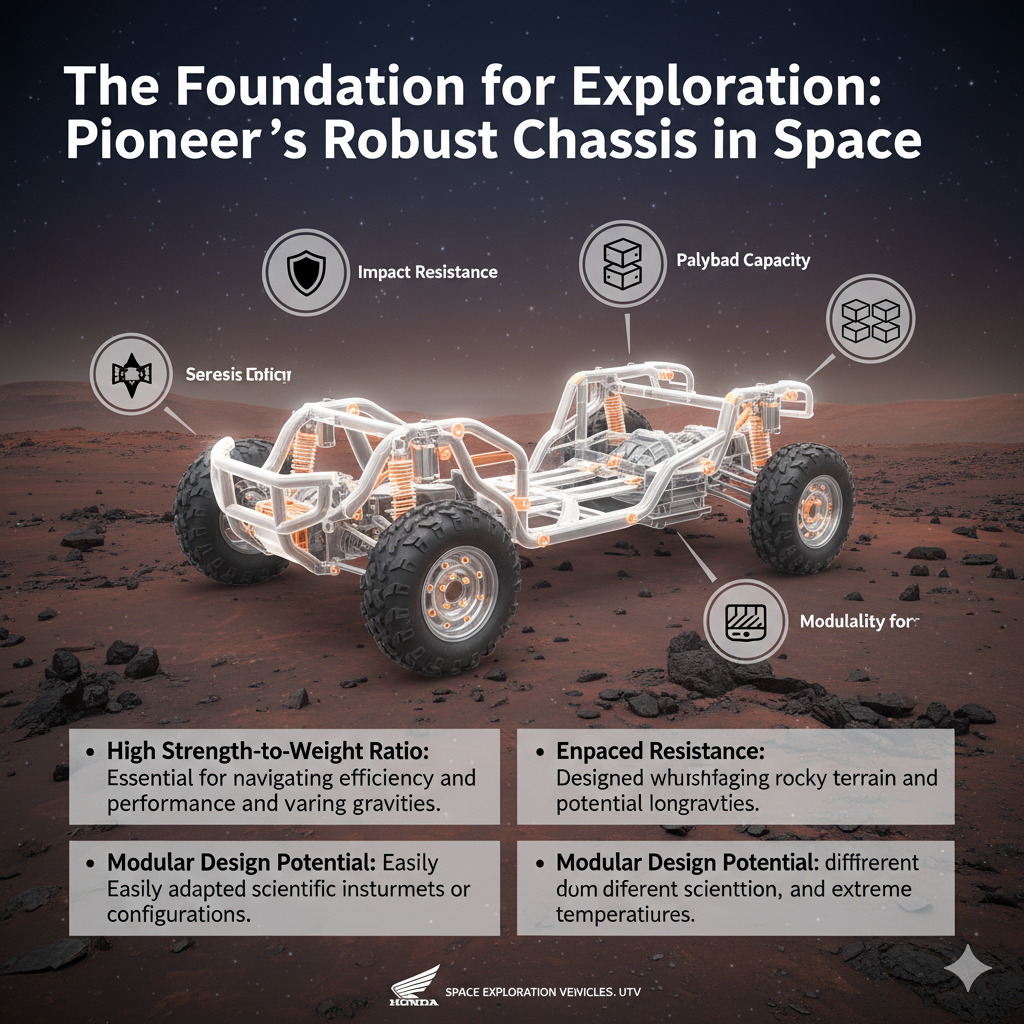

2. Chassis and Suspension: Built for the Void

The Pioneer’s robust, heavy-duty chassis is built to withstand years of abuse on Earth.

This same design philosophy translates perfectly to a space rover.

- High-Strength Steel Frame: The Pioneer’s frame is over-engineered for its application. This strength is needed in space to support heavy payloads, complex scientific instruments, and the massive battery packs required for electric propulsion.

- Independent Suspension: The Pioneer’s Independent Rear Suspension (IRS) allows each wheel to move independently, maximizing ground contact over uneven terrain. On the Moon, with its deep craters and boulders, this is essential for stability and preventing rollovers.

- Adaptation: The Wheel-Leg System: A lunar Pioneer wouldn’t use pneumatic tires. Instead, the Pioneer’s suspension mounting points could be adapted for a flexible metal mesh wheel or a wheel-on-leg system (like the Mars rovers) that allows for greater articulation and obstacle clearance. The robust A-arms and shock mounts would provide the perfect anchor points for this advanced system.

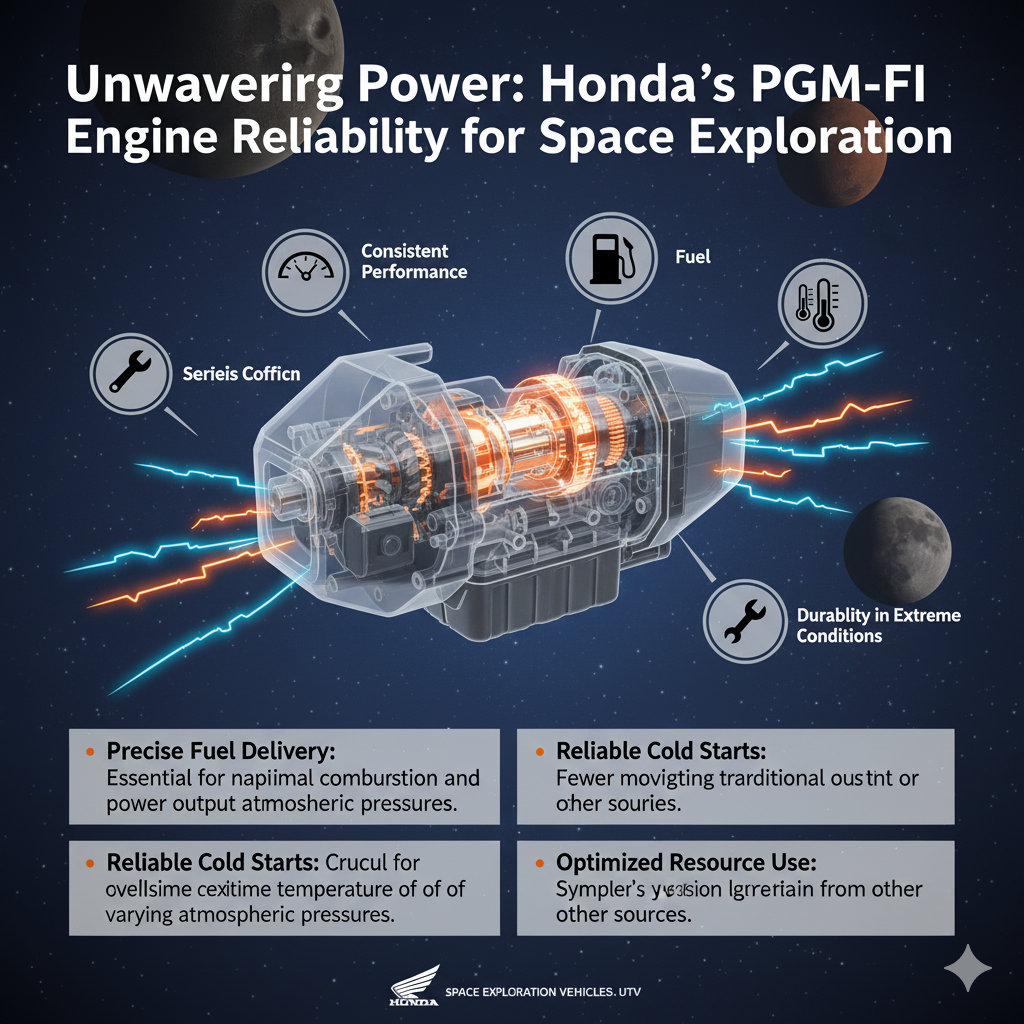

3. PGM-FI and Reliability: The Honda Ethos

While a Martian Pioneer would likely be electric, the core principles that make the Programmed Fuel Injection (PGM-FI) system so reliable on Earth are what Honda brings to the table.

- Sensor Redundancy: PGM-FI relies on a complex network of sensors to manage the engine. In a space application, this translates to sensor redundancy for the electric motors and battery management system. Honda’s engineering standard demands that a system must have multiple layers of backup to prevent mission-critical failure

- Ease of Maintenance: The Pioneer is designed for field maintenance. This is a non-negotiable for a space vehicle. Every component must be easily accessible and replaceable by an astronaut in a bulky suit. The Pioneer’s simple, modular design philosophy—where the engine and transmission are easily separated from the chassis—is ideal for lunar base repair bays.

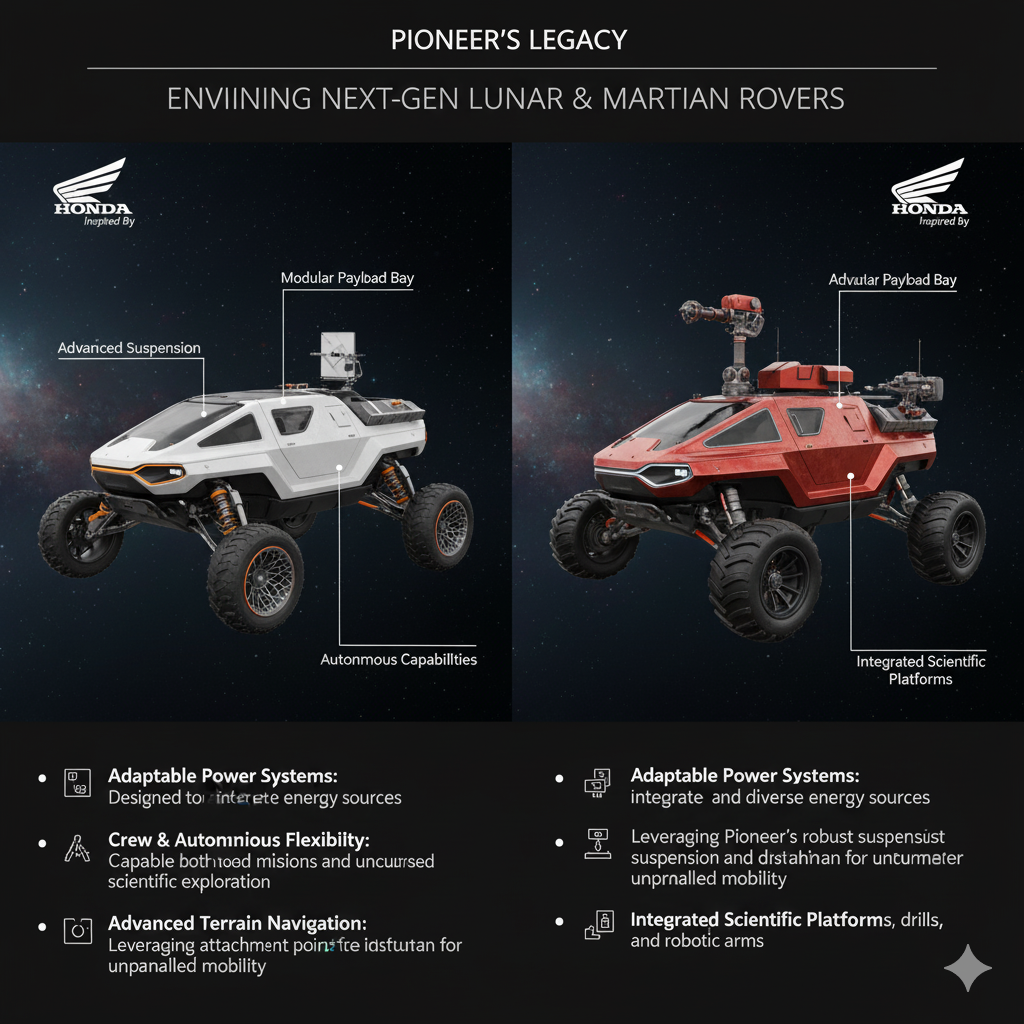

The Lunar Pioneer Concept: Utility in Zero-G

Imagine a specialized Lunar Pioneer 1000-6 adapted for the Moon:

- Pressurized Cabin: The six-seat configuration is replaced with a small, pressurized cabin for two astronauts, allowing them to travel without their suits for short durations.

- Utility Bed: The rear bed is replaced with a universal docking port for scientific equipment, including drills, sample collectors, and communication arrays.

- Power Source: The engine is replaced by a massive, high-output Lithium-Sulfur battery pack charged by a deployable solar array mounted on the roof.

The journey from the legendary ATC to the modern Pioneer has been one of relentless innovation and a commitment to reliability.

It’s this very commitment that makes Honda’s technology a surprisingly perfect candidate for the next great frontier.

The next time you’re loading up your Pioneer for a weekend trip, remember: you’re driving a machine that is, in spirit and design, ready for the stars.

References & Further Reading

- NASA’s Next Generation Lunar Rover Program [1]

- Challenges of Martian Regolith on Mechanical Systems [2]

- Dual Clutch Transmission (DCT) in Extreme Environments [3]

- Honda’s Role in Robotics and Advanced Mobility [4]