As a proud owner of a Bad Boy mower, you understand the importance of a well-maintained machine – ( This Post is all about with details and infograpics and other sources – bad boy mower carburetor. diagram )

These powerful zero-turn mowers are built for performance, but like any intricate piece of machinery, they require attention to detail to keep them running at their peak.

At the heart of your mower’s engine lies the carburetor, a crucial component responsible for mixing fuel and air in just the right proportions.

When your carburetor isn’t performing optimally, your mower’s efficiency, power, and even its ability to start can be severely impacted.

This comprehensive guide will walk you through everything you need to know about your Bad Boy mower’s carburetor.

Videos are added as random thoughts 💭 💭…

We’ll explore its function, common issues you might encounter, and practical steps for troubleshooting and maintenance.

By the end, you’ll be equipped with the knowledge to keep your Bad Boy roaring and your lawn looking pristine.

What Exactly is a Carburetor and How Does It Work?

Think of the carburetor as the lungs of your mower’s engine.

Its primary job is to create a combustible mixture of fuel and air, which is then ignited to produce the power that drives your blades and wheels.

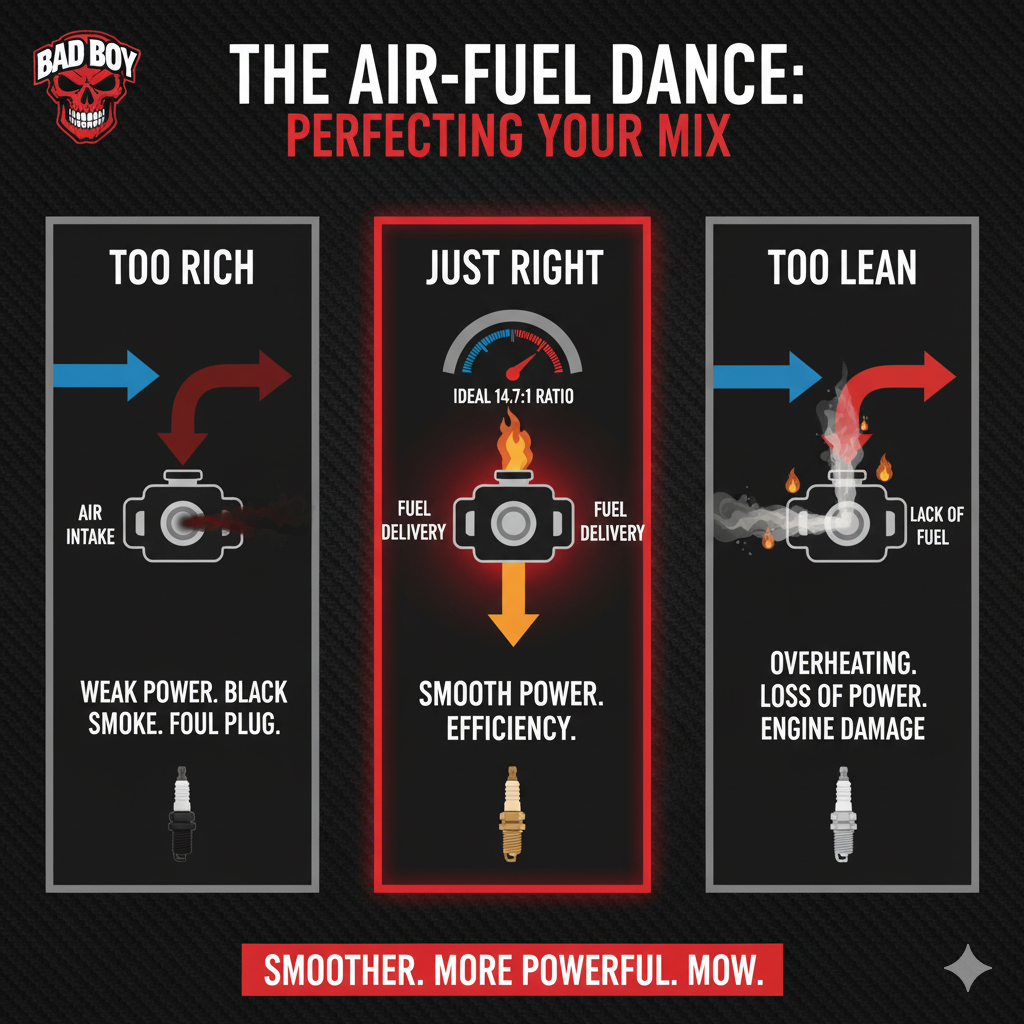

This delicate balance is essential for efficient operation.

Too much air or too much fuel, and your engine will either struggle, run poorly, or refuse to start at all [2].

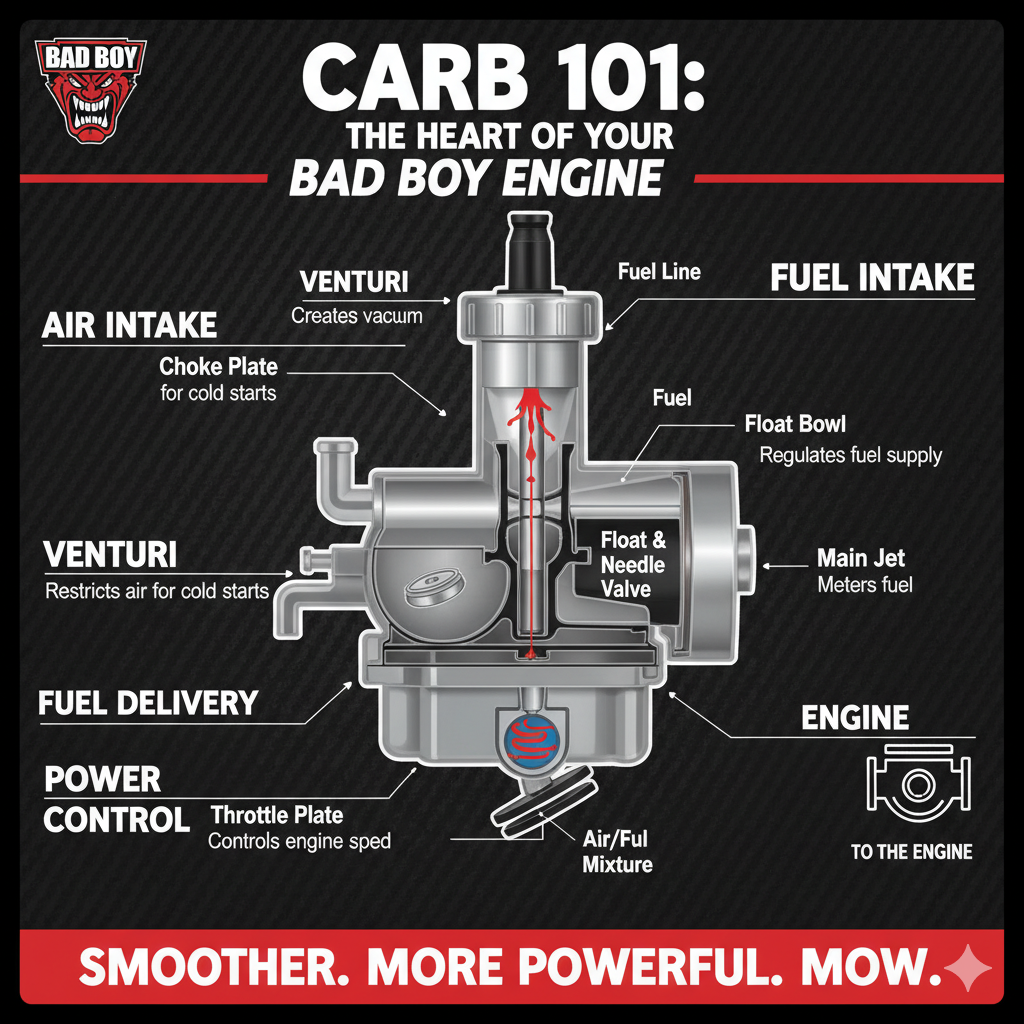

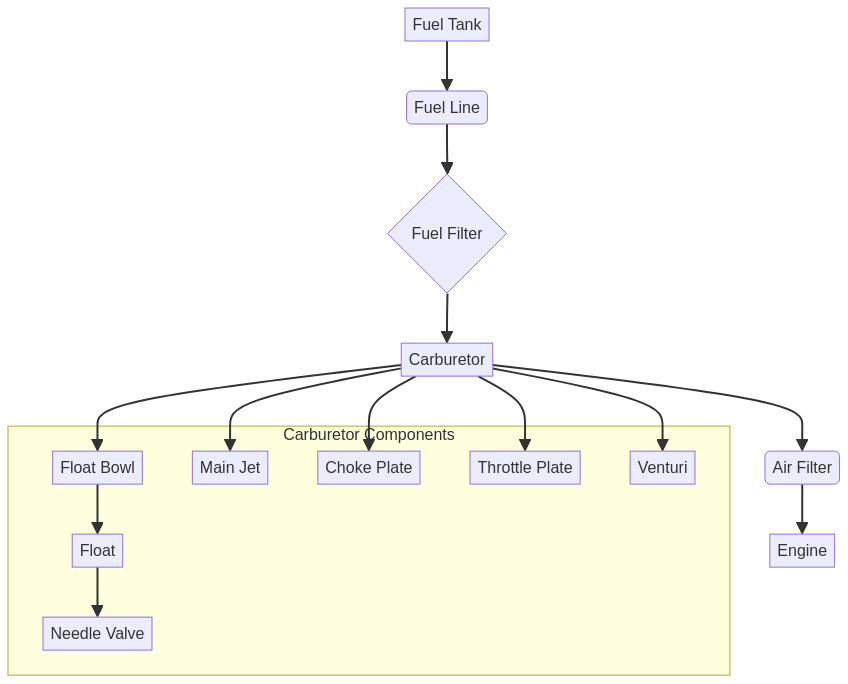

Carburetors achieve this by utilizing the Venturi effect.

As air is drawn into the engine, it passes through a constricted area (the Venturi) within the carburetor.

This constriction causes the air speed to increase and its pressure to drop.

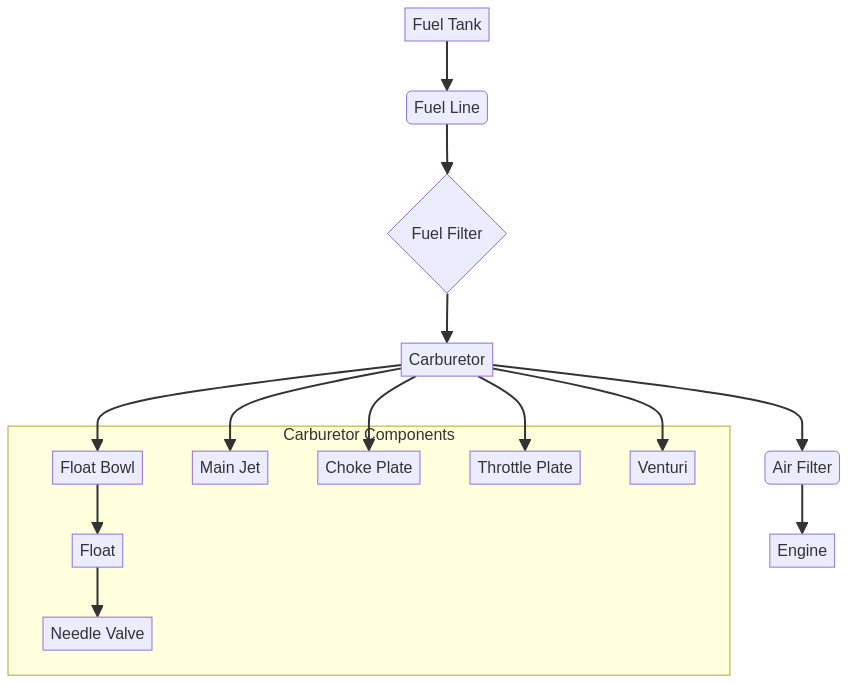

The lower pressure then draws fuel from the float bowl through a main jet, atomizing it and mixing it with the incoming air.

This air-fuel mixture is then sent to the engine’s combustion chamber.

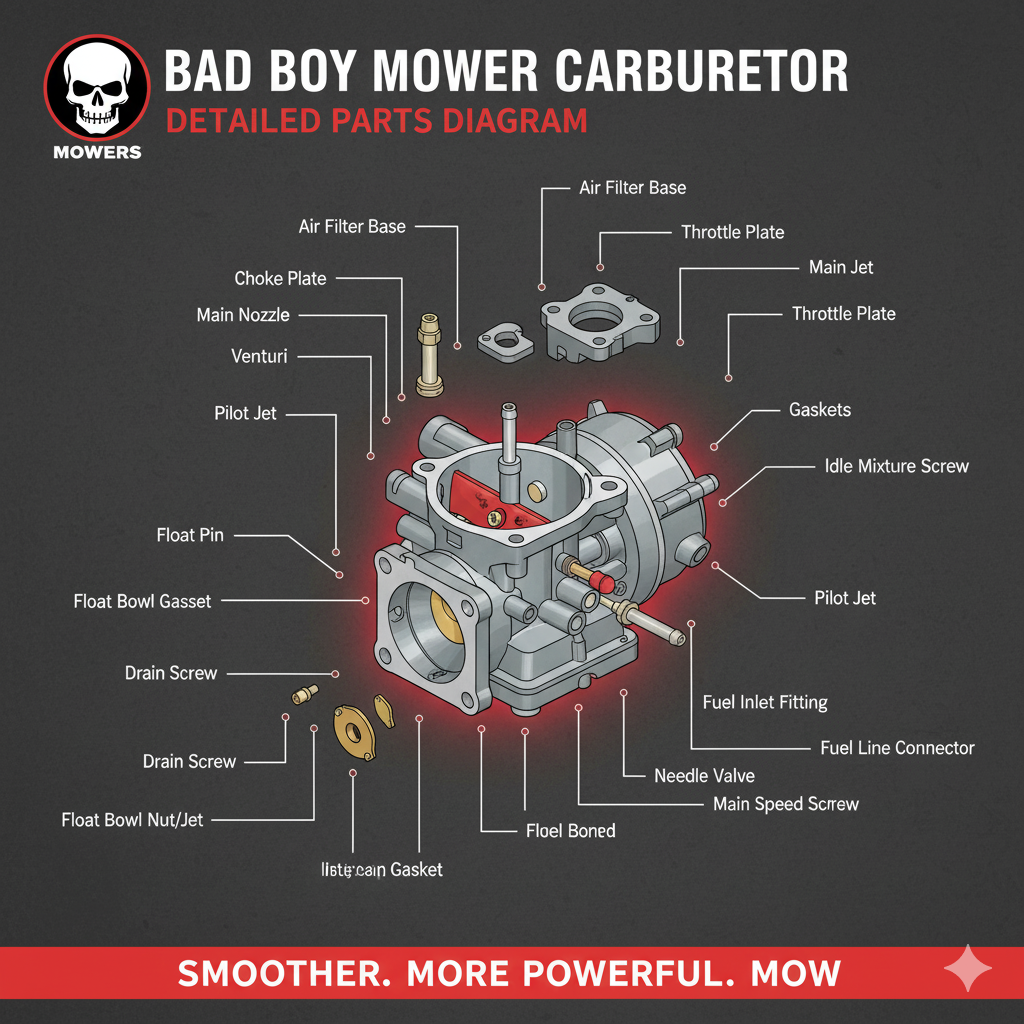

Key components within a carburetor include:

Float Bowl: A reservoir that holds a small amount of fuel.

Float and Needle Valve: Regulate the fuel level in the float bowl, preventing overfilling.

Main Jet: Controls the amount of fuel entering the air stream during normal operation.

Choke Plate: Restricts airflow to enrich the fuel mixture for cold starts.

Throttle Plate: Controls the overall amount of air-fuel mixture entering the engine, thereby regulating engine speed.

Venturi: The constricted passage where air speed increases and fuel is drawn in.

Understanding these basic components is the first step toward diagnosing and resolving carburetor-related issues.

Below is an infographic illustrating the basic flow through a small engine system, highlighting the carburetor’s place within it.

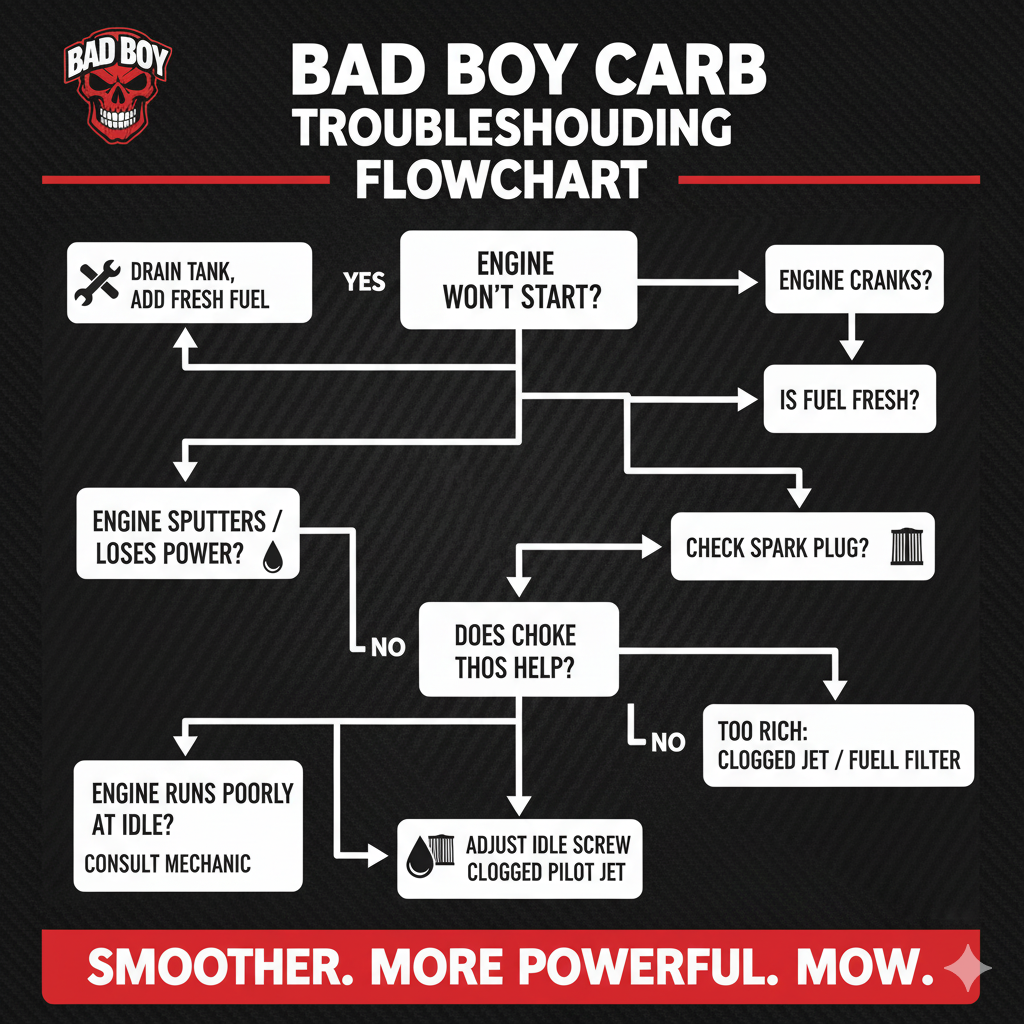

Common Bad Boy Mower Carburetor Issues

Even with regular maintenance, carburetors can develop problems.

Many issues stem from fuel quality or debris.

Here are some of the most common carburetor-related problems Bad Boy mower owners face:

Stale or Contaminated Fuel: Gasoline can break down in as little as 30 days, especially if it contains ethanol and no stabilizer.

This breakdown can lead to sticky residues and clogs within the carburetor’s delicate passages [1].

Clogged Jets: The main jet, responsible for fuel delivery, can become clogged with debris or fuel varnish, leading to an improper air-fuel mixture.

Symptoms include rough running, loss of power, or the engine only running on choke.

Dirty Float Bowl: Sediment and debris can accumulate in the float bowl, interfering with the float and needle valve’s operation, leading to either fuel starvation or flooding.

Stuck Float or Worn Needle Valve: A float that is stuck or a needle valve that is worn can cause the float bowl to either overfill (flooding the engine) or not fill enough (starving the engine of fuel).

Fuel Leaks: Gaskets can degrade over time, leading to fuel leaks around the carburetor.

This is not only inefficient but also a fire hazard.

Air Filter Restriction: While not directly a carburetor part, a clogged air filter severely restricts airflow to the carburetor, leading to a rich fuel mixture and poor engine performance [1].

These issues often manifest as difficulty starting, rough idling, loss of power, excessive smoke, or increased fuel consumption.

The infographic below summarizes some of these common problems and their effects.

Troubleshooting and Maintenance: Keeping Your Carburetor Clean

Regular maintenance is key to preventing most carburetor problems.

If you’re experiencing issues, a thorough cleaning is often the first and most effective solution.

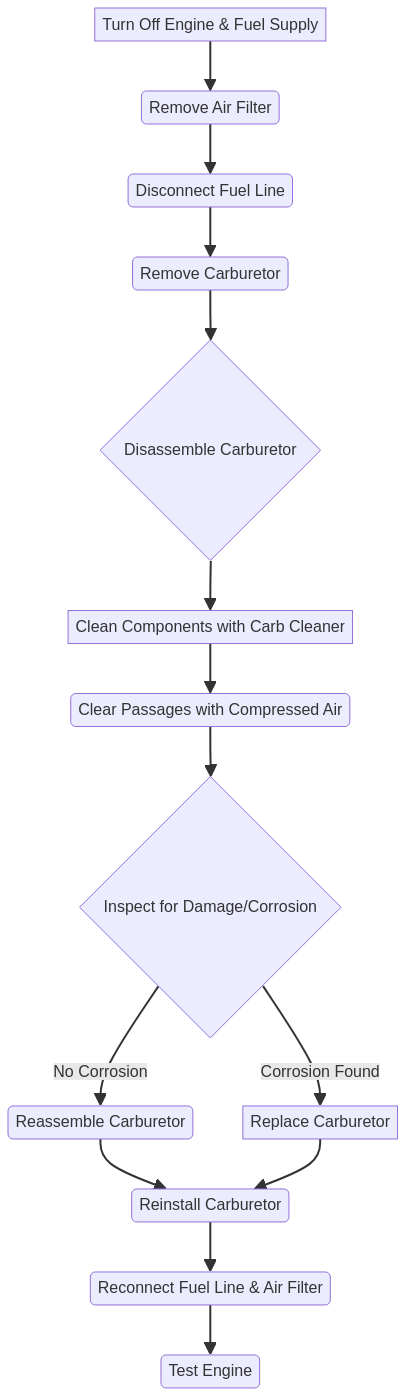

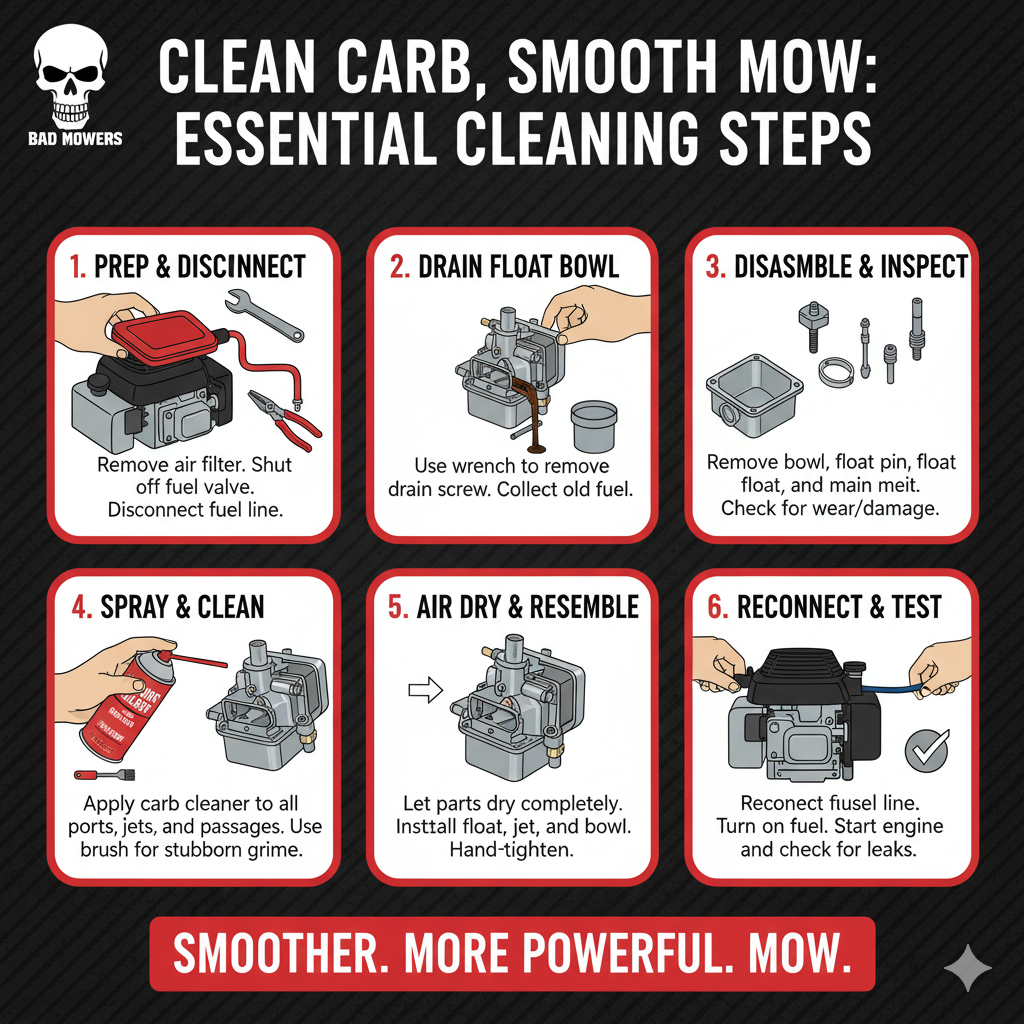

Here’s a step-by-step guide to cleaning your Bad Boy mower’s carburetor:

1. Safety First: Always turn off your mower, remove the spark plug wire, and shut off the fuel supply before beginning any work. This prevents accidental starts and fuel spills.

2. Remove the Air Filter: Access the carburetor by removing the air filter housing and the air filter itself. Inspect the air filter and clean or replace it if necessary [1].

3. Disconnect Fuel Line: Carefully disconnect the fuel line from the carburetor.

Be prepared for a small amount of fuel to leak out.

4. Remove the Carburetor: The carburetor is typically attached to the engine with a few bolts.

Use a socket wrench to carefully remove these, noting any linkages or hoses connected to it.

5. Disassemble and Clean: Once removed, carefully disassemble the carburetor.

Take photos as you go to aid in reassembly.

Use a specialized carburetor cleaner to spray all components, paying close attention to the jets and small passages.

You can use a thin wire (like piano wire) to clear any stubborn clogs in the jets [3].

6. Compressed Air: After cleaning, use compressed air to blow out all passages and ensure all parts are completely dry.

This helps remove any lingering debris or cleaner residue.

7. Inspect for Damage: Examine all components for signs of wear, corrosion, or damage.

If you find corrosion, especially on the carburetor body, it might be time for a replacement [2].

Gaskets should also be inspected and replaced if they appear brittle or damaged.

8. Reassemble and Reinstall: Carefully reassemble the carburetor, referring to your photos if needed. Reinstall it onto the engine, reconnect the fuel line, and attach the air filter housing.

9. Test: Reconnect the spark plug wire, turn on the fuel supply, and attempt to start your mower. It might take a few pulls or cranks for fuel to prime the system.

For those who prefer a visual guide, the infographic above outlines the carburetor cleaning process.

Tip: Consider adding a fuel stabilizer to your gasoline, especially if your mower sits for extended periods. This can significantly reduce fuel-related carburetor issues [1].

When to Seek Professional Help

While many carburetor issues can be resolved with DIY cleaning and maintenance, there are times when professional help is advisable.

If you’ve followed the troubleshooting steps and your mower still isn’t running correctly,

or if you encounter complex issues like significant internal damage, persistent fuel leaks,

or difficulty adjusting the carburetor, it’s best to consult a certified Bad Boy mower technician.

They have the specialized tools and expertise to diagnose and repair more intricate problems,

ensuring your mower is safely and effectively restored to optimal performance.

Conclusion

The carburetor is a vital component of your Bad Boy mower, directly influencing its performance and longevity.

By understanding its function, recognizing common issues,

and performing regular maintenance, you can prevent many problems and keep your mower running smoothly.

Remember, fresh fuel, clean filters, and a well-maintained carburetor are your best allies in achieving a powerful and efficient mowing experience.

Detailed Diagram …..

Happy mowing!

—

References

[1] Diamond B Tractors. (n.d.). *Bad Boy Lawn Mower Won’t Start? 9 Steps to Fix It Fast!* Retrieved from [

[2] Gold Eagle Co. (n.d.). *Guide to Lawnmower Carburetors*. Retrieved from

[3] Reddit. (n.d.). *So angry. Teach me how to clean/maintain my carburetor? …* Retrieved from